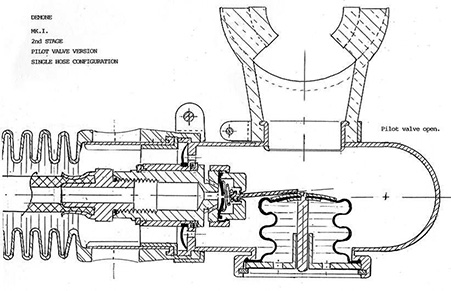

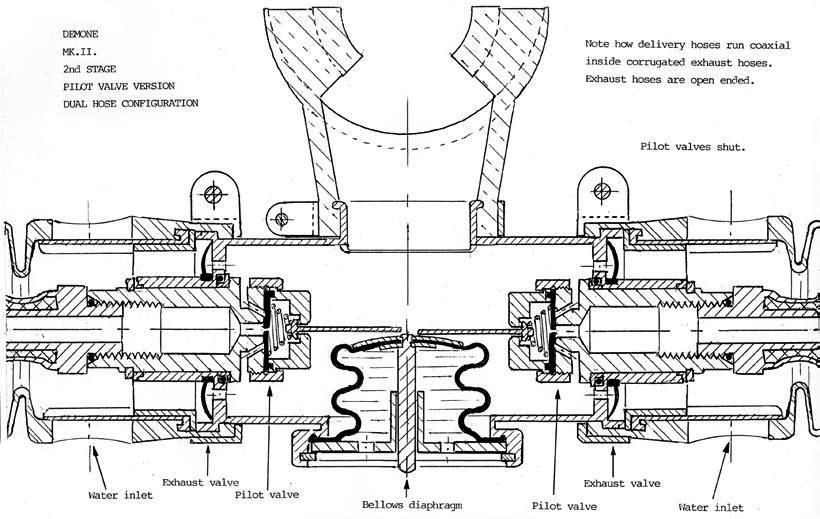

Among the countless products the North American rich and highly competitive sports diving gear market offered during the ’60 years and which stood out for the originality of their technical solutions, although not always leading to the commercial success their inventors expected, it has to be remembered the very strange “Demone” diving regulator, produced in two models Mark I (see Figure1) and Mark II (see Figure 2).

|

|

| Fig. 1 | Fig. 2 |

In those years, to capture the US sports divers audience, who were mostly oriented towards well consolidated and very successful products like those distributed by important brands such as U. S. Divers, Voit or Healthways before and Dacor and Scubapro later, it would have been necessary the offered products had characteristics of novelty and presumed qualitative and performance features to attract the interest of potential customers.

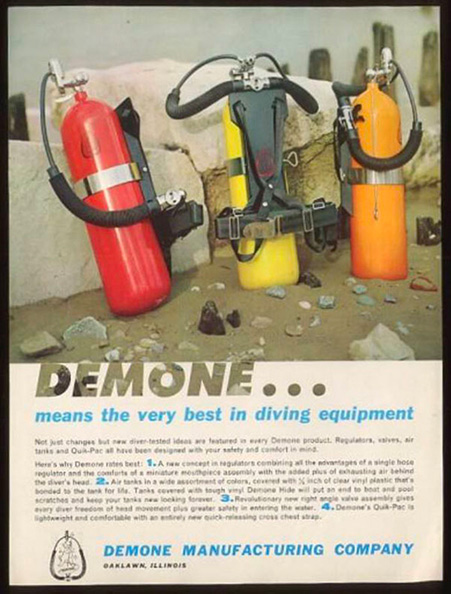

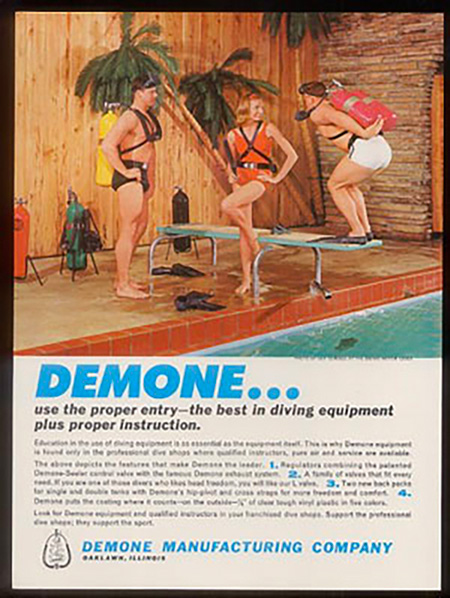

This was indeed the approach tried by the designer Robert J. Dempster and by his partner Al O’Neill in proposing this very strange regulator on the North American sports diving market. The two specially created the “Demone” brand (see Figure 3), a trade-mark which was also engraved on the front area of the second stage body for both models (see Figure 4), and founded the Demone Manufacturing Corporation based in Oak Lawn, Illinois (USA).

|

|

| Fig. 3 | Fig. 4 |

This regulator, in both its versions Mark I (single hose) and Mark II (double hose), remained in production for four years only and precisely from 1962 to 1965.

To understand the basic ideas and the reasons why the designer developed this specific regulator concept, it is necessary to understand the particular historical period during which this product was conceived and launched on the market.

The beginning of the 1960s saw the appearance of the first truly competitive single hose regulators, also in terms of performance, compared to the double hose models that had been on the market for fifteen years and had reached their full maturity.

In particular, having now understood that the latest single hose regulator models introduced on the North American market in those years (see for example the Calypso of the US Divers, the Scubair of the Healthways, the Waterlung Sport Diver of the Sportsways, the Dart of the Dacor, etc.) had very competitive performances compared to those of the best and most popular double hose models (such as the Aqua-Lung DA Aqua-Master and the DW Mistral from US Divers, the equivalent single and double hose models produced by Voit, the several Dacor double hose models, etc.) and that they were also more competitive as production costs, the challenge was in finding an idea to solve the remained main problem of the single hose regulators: the exhaust air bubbles in front of the mask’s glass.

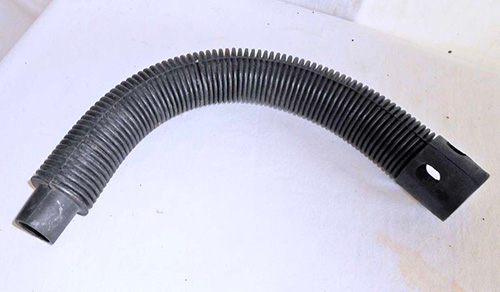

The air discharge problem was solved by Robert J. Dempster using a corrugated hose, similar to that installed on the double hose regulators for the inhalation and exhalation phases (see Figure 5) mounted coaxially with respect to the low pressure hose feeding compressed air from the first stage to the second stage (see Figure 6).

|

|

| Fig. 5 | Fig. 6 |

This corrugated hose had the purpose of channeling the exhaled air flow behind the diver's shoulders, in a similar way to what happened with the double hose regulators, thus avoiding producing the annoying bubbles in front of the diver’s mask.

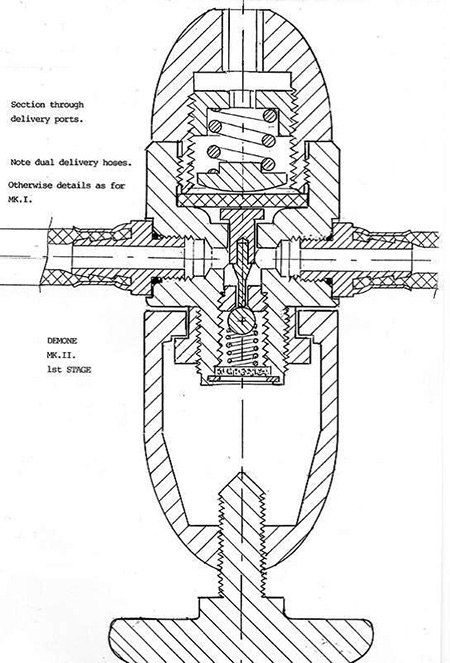

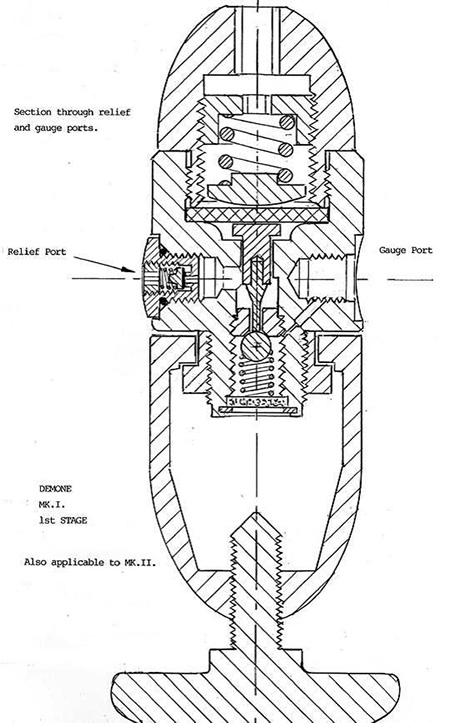

Let's now deeply analyze the construction details and the main technical solutions adopted on these models. We start from the first stage which was a typical unbalanced diaphragm type first stage, as shown in Figure 7 and Figure 8.

The operating scheme and the main components of the first stage are illustrated in Figure 9 and in Figure 10. As you can see the main novelty element in the construction of the first stage of this regulator was the sealing element between the high pressure and the intermediate pressure sides, an element consisting of a stainless steel ball and a conical seat in plastic material. Curiously, the same solution would have been recently adopted by Poseidon for the current production Xstream regulator.

|

|

| Fig 7 | Fig. 8 |

|

|

| Fig. 9 | Fig. 10 |

As can be seen by looking at the cross-section of Figure 10, a maximum pressure relief valve was mounted in the body of the first stage, a component which is necessary to include whenever you were dealing with an “upstream type” second stage valve, as we will see below. In fact, in the event of air leaks in the first stage, this type of valve was unable to discharge the overpressures arising in the pneumatic circuit between the first and second stages of the regulator, with the risk of bursting of weakest components of this circuit. These components were normally the low pressure hoses.

In fact, this type of valve was also adopted on Demone regulators as shown in the diagrams of Figure 11 and Figure 12 for the single hose model Mark I.

|

|

| Fig. 11 | Fig. 12 |

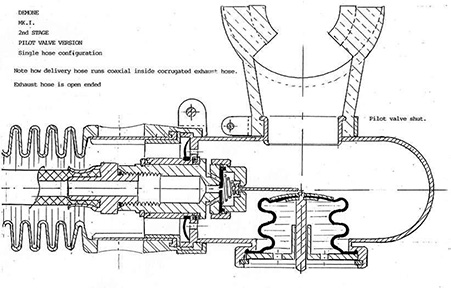

It was the classic tilt valve, adopted in those years on many competitive models, as an alternative to the classic "downstream" valve which would later become the standard for almost all regulators in the following years and up to the present day. In the first versions of this regulator, the tilt valve was conceived as a direct-operated valve but subsequently, to drastically increase the air flow, the second stage valve became of the "piloted" type. In this second version, shown in the diagrams of Figure 11 (with tilt valve not actuated) and of Figure 12 (with tilt valve actuated), the tilt valve was used only to trigger the pilot pneumatic flow which would then open the main valve sealing element. This element, in the case of the Demone, consisted of a small circular diaphragm with a small central orifice which, when the pilot flow was triggered, was deformed by the air pressure drop across the orifice towards the tilt valve thereby opening the main air flow passages. The same principle would later have been used also on the Oceanic Omega II regulator many years later (1984).

The other technical choice to highlight on this model was the adoption of a cylindrical bellows replacing the classic circular balancing diaphragm. This choice had the specific purpose of reducing the front section of the regulator second stage making it lighter and more hydrodynamic. In this case the air purge button was replaced by a thin cylindrical pin that could still be operated by the diver's hand (see also Figure 4).

Finally, let’s describe the air exhaust discharge system which was undoubtedly the most innovative element of this regulator. This consisted of a ring-shaped rubber mushroom valve mounted between the central body of the second stage supply valve and the side of the second stage body. On this tubular part of the body, the external corrugated hose was installed for the discharge of the exhaled air. As can be seen in the diagrams of Figure 11 and Figure 12 but also in Figure 5, the initial part of this hose, in the area overlapping the tubular body of the second stage, had circular housings to allow water filling quickly the corrugated hose itself so improving the discharge phase of the exhaled air. An additional tubular rubber element was mounted between the corrugated hose wall and the inlet sleeve of the second stage. This element allowed water entering from the outside but prevented any air flow across the corrugated housings during the exhalation phase. The exhaled air was thus forced to cross completely the corrugated hose until its top end in such a way it was discharged well away from the diver's mask.

Not still happy with all these innovations and wanting to offer something really superior to everything that existed then on the market, the designer decided to also propose a "De-Luxe" version of this regulator. The Mark II model was therefore born with a double delivery valve in the second stage and low pressure double hoses connecting the two stages. The operating scheme of this model is shown in Figure 13.

|

| Fig. 13 |

In addition of the theoretical technical advantages that this solution proposed, i.e. the complete redundancy of the second stage delivery valve and the consequent increase in the air flow rate during the inhaling phase, the designer hoped to earn the interest of those divers already familiar and comfortable with the double hose regulators and hesitant to embrace the diving techniques requested by the new single hose regulators. With the Mark II Dempster hoped to offer this population of divers, rather conservative regarding the choice of new equipment, all the performances and the typical advantages of single hose regulators without however changing the methods of use and renouncing the positive aspects of the double hose regulators.

The launch on the market of these innovative products was strongly supported by a specific advertising campaign (see Figure 14 and Figure 15) which sought to highlight the strong innovative content of these products and the exceptional performance that they would have guaranteed to future customers.

Unfortunately, as often happened to these products with highly innovative contents launched on the market in those years but designed and developed without applying rigorous scientific criteria and put into production without going through robust campaigns of tests and validations in the field, the Demone, both in the Mark I and in the Mark II versions, was another technical and commercial "flop", as demonstrated by the very few years of production (from 1962 to 1965) and the few units produced in total.

Let's try to understand where the "Achilles heel" of this self-contained breathing apparatus was. The phenomenon that Dempster had underestimated was precisely the phase of air discharge that should have brought the amount of air exhaled by the diver from inside the second stage to the upper end of the corrugated hose (or corrugated hoses).

|

|

| Fig. 14 | Fig. 15 |

The mass of water inside the corrugated hoses had such a mass that, in order to eject it quickly together with the exhaled air, the diver had to apply a considerable pulmonary effort with the risk of exhaust him in a short time and triggering situations of respiratory distress.

The other negative element that emerged during the use of this regulator was the risk of salt, sand and debris accumulation inside the corrugated hose (or corrugated hoses) with further deterioration of the exhalation performance of the regulator and the need for frequent disassembly and cleaning of the internal area of the corrugated hoses.

After closing the unlucky Demone adventure, the American company continued the production of other articles for sports diving but with the new Demco Products brand.

As well as for other diving equipment that remained in production for a short time and were manufactured in a limited number of units, the Demone regulator, both in the Mark I and in the Mark II versions, is now considered a very rare piece among the collectors of vintage diving gear.

_______________