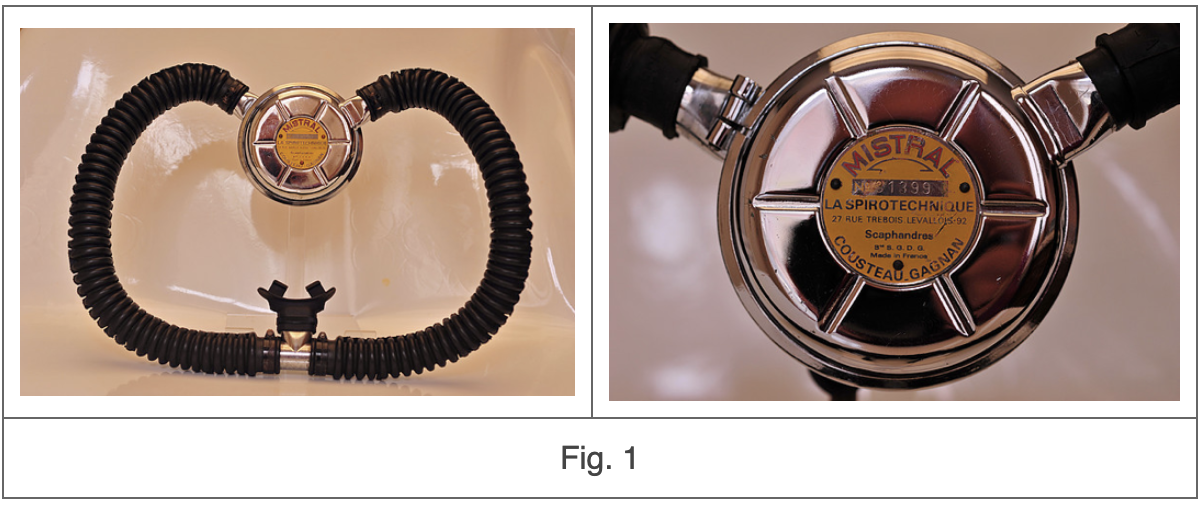

Although almost unknown to the nowadays hyper-technologic and over-geared scuba divers, the mythical Mistral regulator (Fig. 1) has been the inseparable dive buddy for several generations of divers having the opportunity of exploring the almost uncontaminated sea floors along our seacoasts during the early times of this sport.

We are talking about the ‘50 and ’60 years when the so called “tribe of the rocks”, as defined by the great Duilio Marcante, faced dives with passion and enthusiasm using the gears available at that time, which were significantly more primitive and less performing than the modern ones.

Among them, the Mistral was undoubtedly one of the basic and more common components since it was used not only by the early sports divers but also by many professional and military organizations of that period. However this regulator, in the configuration used and appreciated by many Italian divers in those years, was the result of a long and patient design and development effort carried out by the engineer Emile Gagnan who, from his Montreal’s laboratory in Canada, created and developed ideas and patents for his employer, the French company Air Liquide, along his whole work career which ended in 1980.

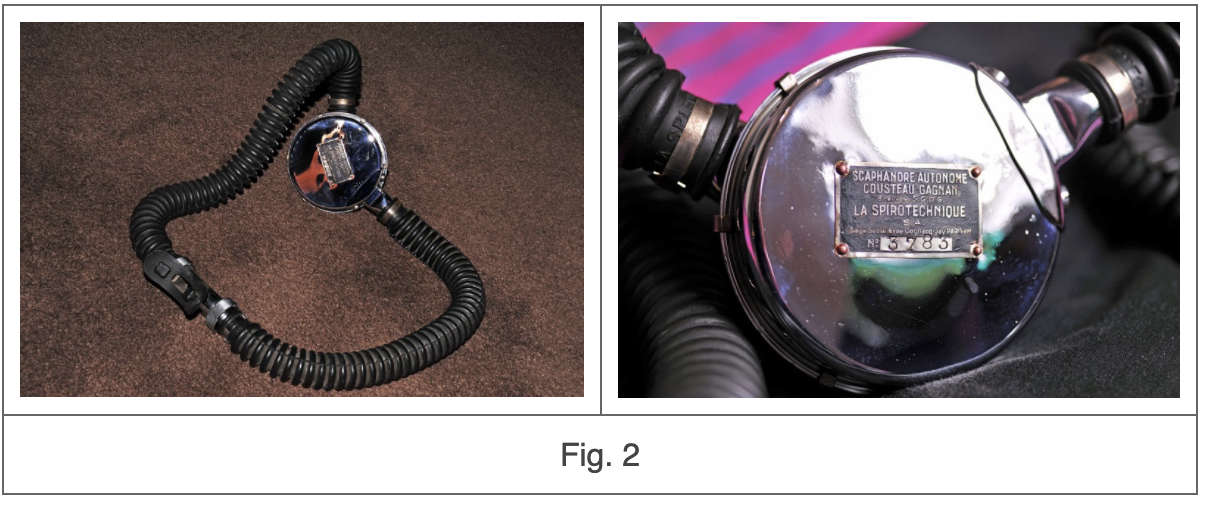

Gagnan indeed, after the launch in 1946 of the first compressed air scuba model, the famous CG-45 (Fig. 2), patented with J. Y. Cousteau e manufactured by La Spirotechnique, a specific brand created by the Air Liquide Company for the distribution of this product, in 1947 moved to Montreal, Canada at the Canadian Liquid Air Ltd factory.

From that location, he would have led for many years the design and development of the most important regulator models manufactured by the French company and by its main licensees all around the world. The emigration to Canada of Gagnan and his family was warmly encouraged by his employers who have properly predicted the huge potential of the North American market versus the European one. This latter was still recovering with difficulty from the disasters of the WWII and therefore could not ensure soon a consistent request of similar equipment. For this reasons many improvements and upgrades Gagnan implemented on both the CG-45 and the following regulator models, basically remained unknown in Europe, including Italy.

The main problem bothering Gagnan about performances of the CG-45 regulator was the considerable inhalation effort requested by this model; this inhalation effort well exceeded the values we are familiar with the modern regulators. Well-exercised divers only could dive with this regulator with no risk of shortness of breath, even at shallow depths. And in fact it was not a coincidence that the early users of this regulator were mainly professional and military divers. Moreover Gagnan, a very demanding and refined designer, was not pleased with the CG-45 which, in addition of its performances limitations, still considered a solution too complex from the manufacturing standpoint, pretty expensive and of difficult maintenance. Therefore, in parallel with the continuous improvement work on the CG-45 basic design, he dedicated himself also on the development of a simpler and more essential model, which would have become the Mistral.

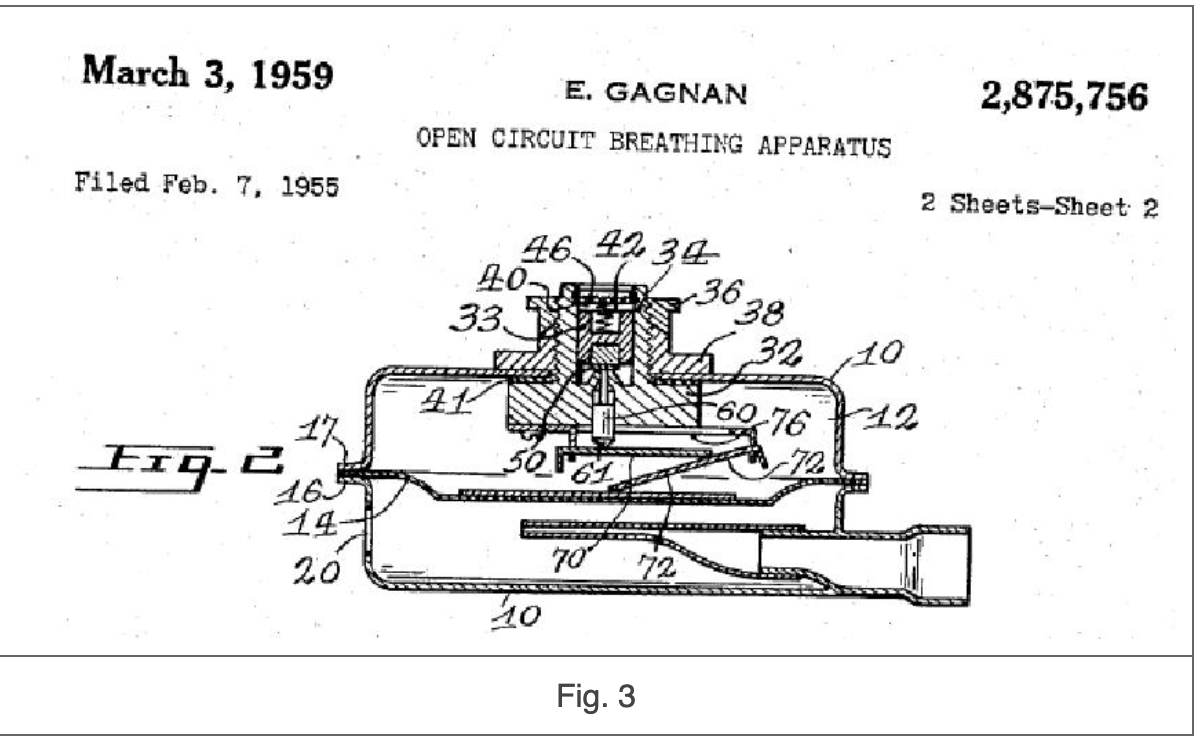

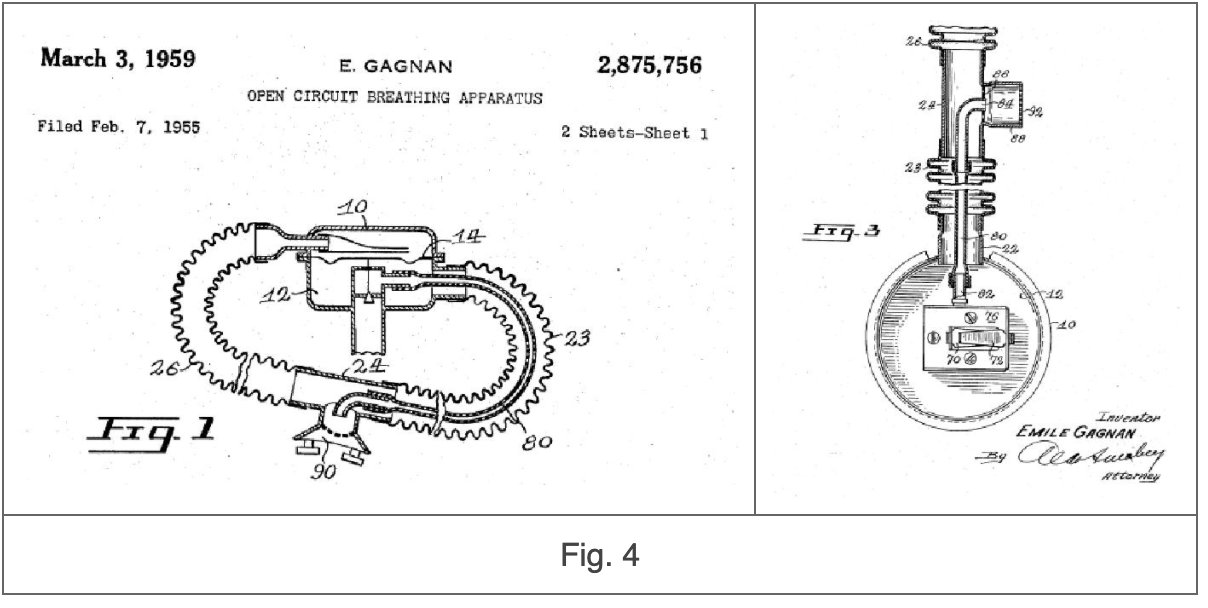

For this reason, Gagnan on February 7th 1955 applied to the US patent office for two distinct patent requests: the number 2,875,756, patented on March 3rd 1959 and the number 2,878,807, patented on March 24th 1959. Regarding these two patents, the first curiosity to be noted is that the only inventor indicated in both these patents was Gagnan only and not J. Y. Cousteau any longer. Conversely this latter was included in the inventors list of the patent application number 2,485,039 for the CG-45 regulator. This request was filed in the USA on March 10th 1947 and patented on October 18th 1949. However, despite this new situation, La Spirotechnique continued to associate the Cousteau’s name to that of Gagnan not only on the Mistral’s nameplate but also on those of the regulators models produced later. Off course that decision was taken mainly for commercial and advertising reasons, considering the celebrity the Cousteau commander was achieving all around the world thanks to his documentaries on the marine explorations. It was then convenient in writing “Cousteau-Gagnan Patent” although, after the joint CG-45 experience, Gagnan continued to invent new models and solutions without the contribution of the famous French oceanographer

The first fundamental decision taken by Gagnan, at the early development stage of the new model, was to use a pressure reducing valve based on a single stage mechanism instead of on a two stages one which was indeed the solution utilized on the CG-45. This choice would have dramatically reduced the complexity of the regulator (and the related manufacturing costs as well). As consequence of that decision, the forces necessary to open the high pressure seat through the main pressure balancing diaphragm would have been significantly bigger. Gagnan solved this problem using a simple and smart mechanism working by two levers, which was capable to reduce the operating force at the diaphragm level. This mechanism would have amplified the available force produced by the diaphragm, when the diver started inhaling, to a value sufficient to open the high pressure seat (Fig. 3). This result was achieved without reducing too much the size of the air flowing ducts inside the pressure reducer so preventing an excessive limitation in the air flow rate at the dive deepest conditions.

Gagnan did not claim this double lever solution within his two patent applications described above, because this mechanism has been already invented before by William P. Yant (US patent n° 2,318,827 of May 11th 1943). This is the reason why you can find the same mechanism on other regulators produced by several manufacturers during the following years.

Anyhow the most difficult problem to solve was the significant reduction of the diver inhaling effort and therefore the several solutions proposed by Gagnan to achieve this target formed the claims of the two above patents. In fact, as himself clearly described in the introductory part of the two patent applications, in the CG-45 the pressure balance with the ambient pressure in the air flow generated by the regulator, occurred inside the regulator case and therefore the diver had to literally suck the requested air to inhale with remarkable breathing effort. This situation could then worsened when the diver was in those specific positions or swimming conditions locating the regulator case over the diver’s lungs (i.e. swimming with body horizontal and diver facing down).

It was then necessary moving the pressure balancing area in the air stream as much as possible closest to the diver’s mouth, as it happens in the modern two stages single hose regulators. This target was achieved by Gagnan in two different ways and each of them produced a distinct patent request. The first request, number 2,875,756, was based on the addition of a small air ejecting tube, coaxial to the breathing intake hose and installed between the pressure reducing valve and the mouthpiece. This tube conveyed most of the air flow generated by the pressure reducing device directly into the mouthpiece, where the air stream was injected into the diver’s mouth through three small nozzles. From these nozzles, the air stream was flowing at high speed so creating a “sucking” effect making easier the inhaling of the remaining part of the air stream inside the intake hose (Fig. 4). This vacuum effect produced on the diaphragm a positive force capable of further reducing the breathing inhale effort. Although this word was never named explicitly in the two patent applications, for the first time the “Venturi” effect application to these equipment was born; this effect will become a constant until nowadays.

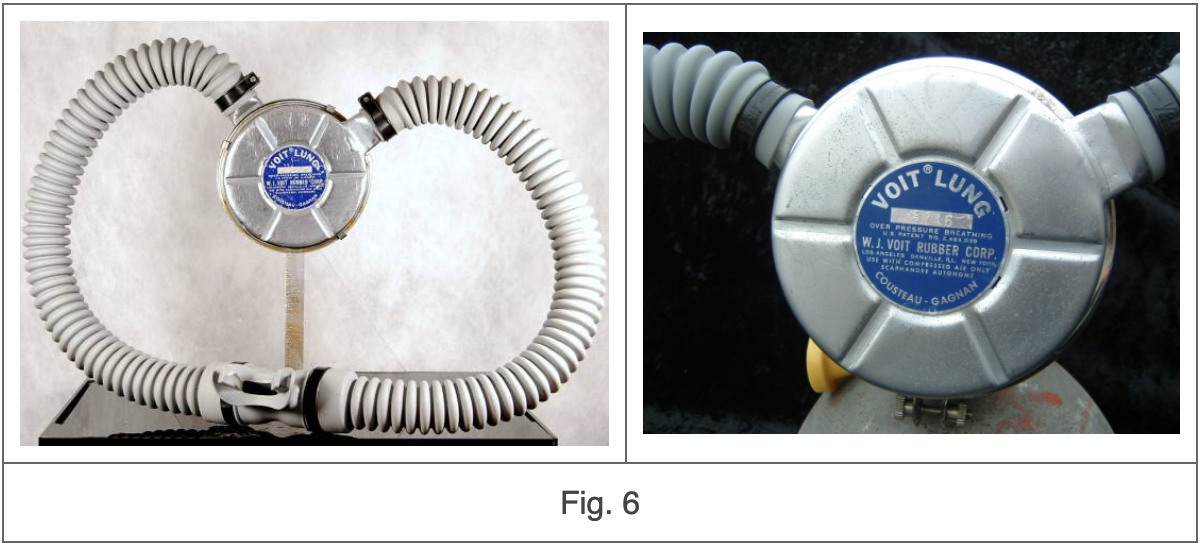

The air flowing inside the internal tube, not being in connection with the main diaphragm, was at a pressure higher than the ambient value (over pressure) until its injection through the small nozzles embedded in the mouthpiece. For this reason indeed the first regulator introduced on the North American market in 1954 by the U. S. Divers Inc. and working on this principle, was named “over pressure breathing” (Fig. 5)

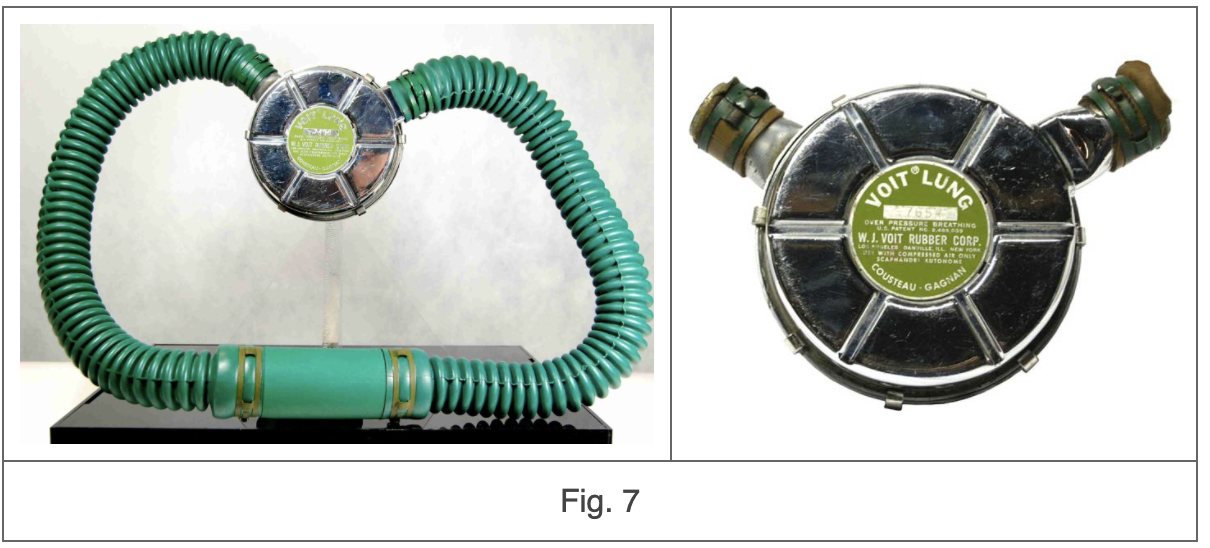

As can be noted looking at the nameplate of this first single stage model put on the market, the patent number 2,485,039 is indicated which in reality was the patent for the CG-45 regulator model. This is rather logical considering that the main claims of the original patent for the CG-45 applied also to this single stage regulator and that the two patent applications for the single stage regulator were filed the year later (1955) and officially released not before than 1959. The interest for this new solution was immediate and, in fact, the Voit Rubber Corporation, an US company having established a manufacturing agreement under license with the U. S. Divers Inc., introduced this model in their price list by presenting two versions: the VR-1 Sportsman in 1955 (Fig. 6) and the VR-1 Mariner in 1956 (Fig. 7).

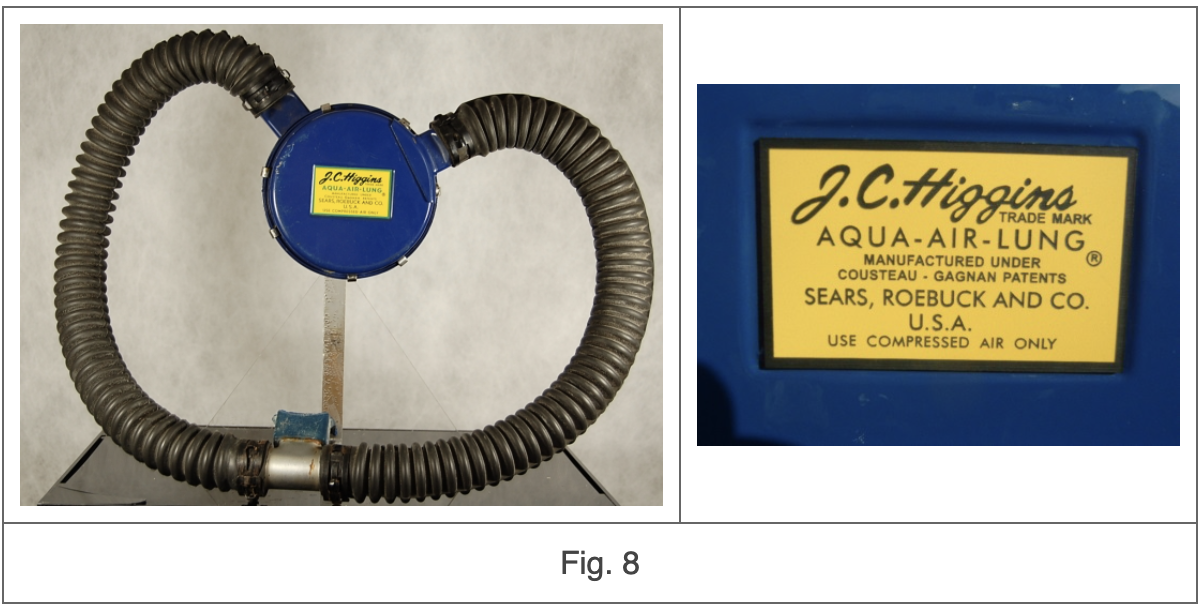

Beside to Voit, another US great distribution firm the Sears, Roebuck and Co., a company which would have become the Sears, Roebuck and Co. Vs Wal-Mart Stores Inc., made an agreement with the U. S. Divers Inc. for the sale of this regulator which was distributed, starting from 1956, with the name “J. C. Higgins Aqua-Air Lung” (Fig. 8).

It should be noted that the “Mistral” name was still not appeared although this regulator has been already introduced in the North America market.

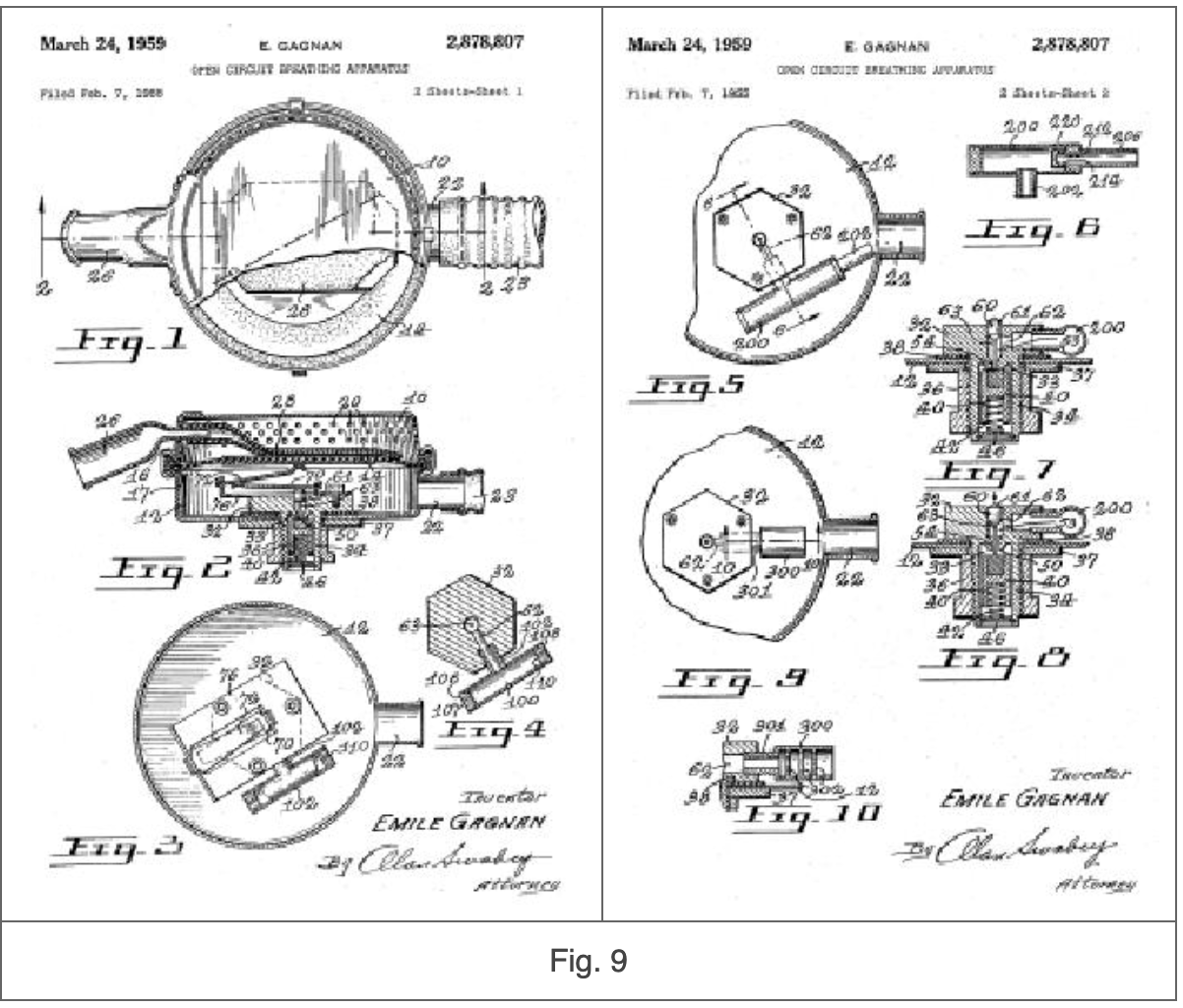

Unfortunately, although its performances in terms of inhalation effort were significantly better than those of the CG-45, including all its variants, the users of this new regulator claimed an unpleasant feeling of air flow literally “shoot” into the mouth. For this reason, Gagnan focused himself on the solution described in his second patent application number 2,878,807. This solution replaced the internal small tube with a nozzle directly installed at the exit of the pressure reducing valve and designed and oriented to obtain the same result of the previous solution but preventing the annoying the violent air flow jet inside the diver’s mouth (Fig. 9).

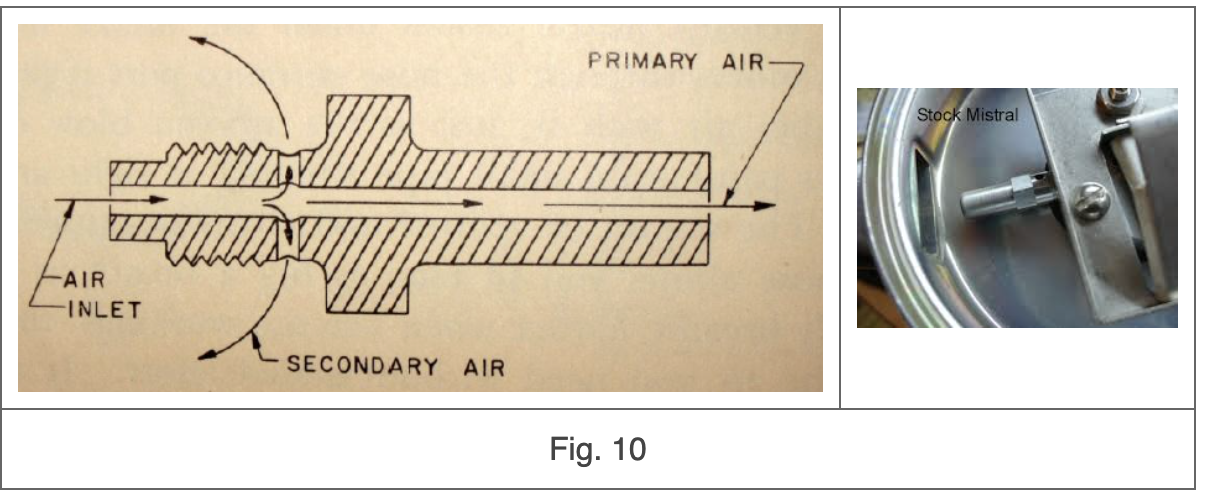

The Gagnan’s idea was to generate a high speed air flow towards the intake hose axis in such a way to move the air stream pressure balancing phase as close as possible to the diver’s mouth and to create the suction effect for the whole air stream exiting from the pressure reducing valve. However, as can be seen in the schemes and drawings enclosed in his patent applications, the solutions proposed and tested by Gagnan were numerous. These solutions included the different orientation of the air primary jet flow with respect to the air intake hose axis and also several geometries of the pressure reducing valve air nozzle. The main objective was to reach the best compromise and optimize the following features: rapidity in obtaining the air suction effect, air stream stability along the whole inhalation phase, speed in stopping the air flow at the end of the inhalation phase (no free flow from the regulator), performances almost independent from the tank pressure, etc. After many tests and prototypes Gagnan founded the best compromise was that of using a nozzle with a specific geometry capable to generate a secondary air flow perpendicular to the primary one. The direction of the nozzle axis was moved slightly apart of the air intake hose axis in order to generate a turbulent flow instead of a laminar one (Fig. 10), a much more favorable condition in improving the dynamic response of the regulator.

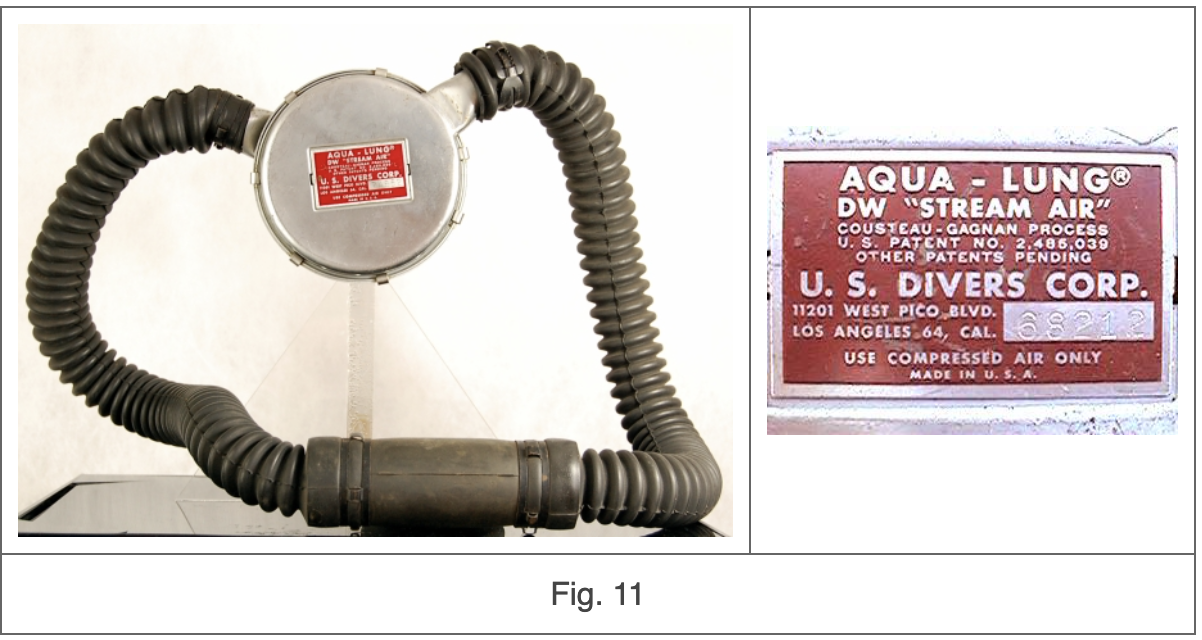

This new configuration of the air injection system, which would have become the final one in the Mistral, in 1956 led to the introduction on the North American market, by the U. S. Divers Inc., of the new model called “Stream Air” (Fig. 11).

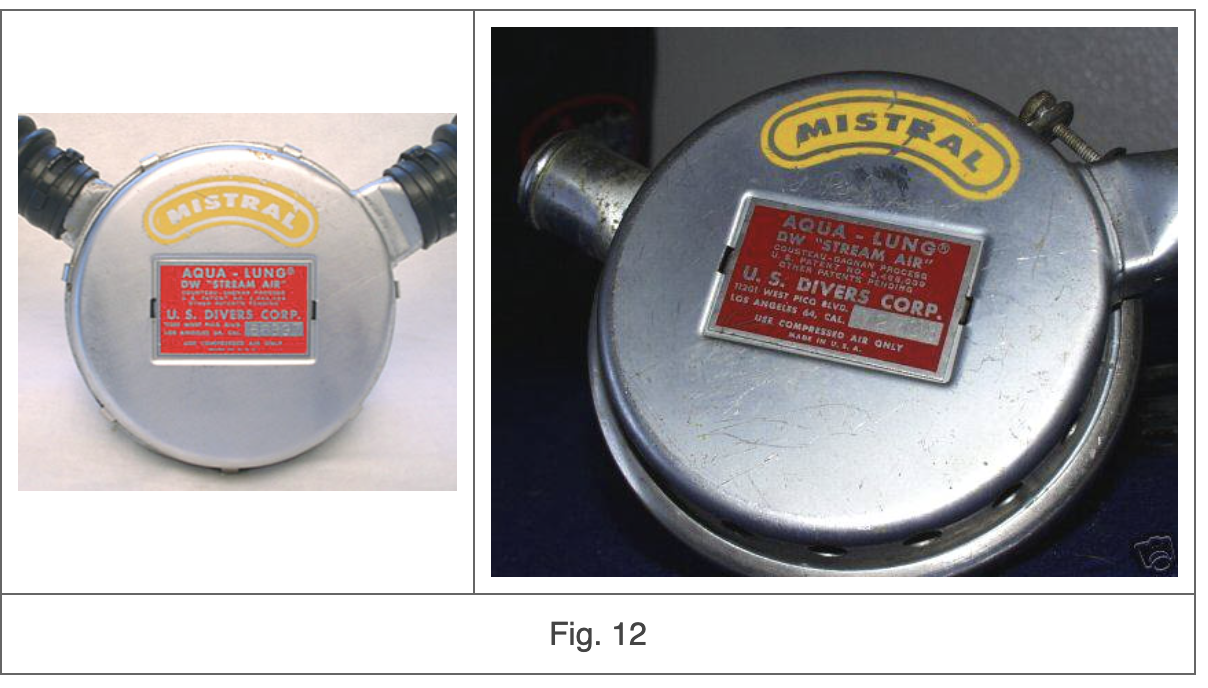

The final name “Mistral”, equivalent in the French language to the Italian name “Maestrale”, would have appeared soon after that date with the yellow Mistral decal applied on the North American single stage regulator models by authorized dealers and dive shops after the units have updated to the latest configuration (Fig. 12).

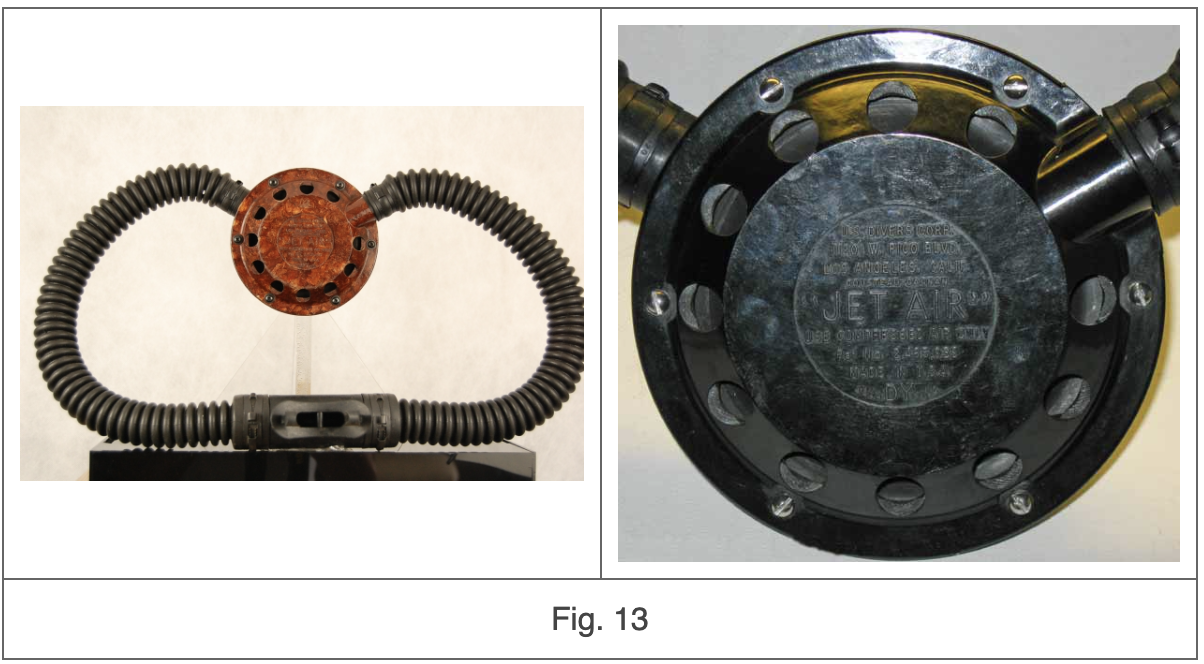

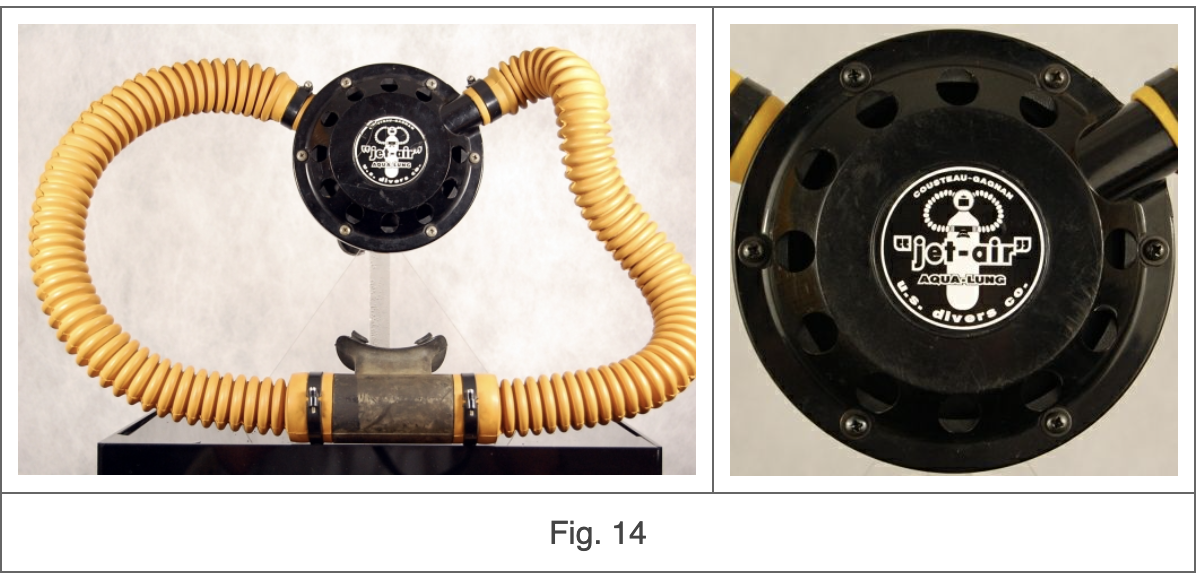

Gagnan had no doubts anymore in believing the Mistral was now ready to successfully replace the CG-45 and from that time indeed he devoted himself to its marketing and commercialization phase also proposing low cost solutions mainly dedicated to dive sports and educational applications. Therefore, the model “DY Jet Air”, manufactured by the U. S. Divers Inc., appeared on the North American market with its main body made of phenolic resin (bakelite) and available in black and brown color (Fig. 13). Starting from 1961, the phenolic resin was replaced by black cycolac resin (ABS) (Fig. 14).

Aware to have found at last the final solution, Gagnan prepared also dedicated transformation kits for the previous models “over pressure breathing”. This retrofit included the installation of a new nozzle and of a new mouthpiece and the removal of the internal piping between the pressure reducing valve and the mouthpiece. And indeed many owners of this first version got their regulators updated to the latest Mistral configuration through authorized dealers and diving shops.

From that time on, this configuration represented the foundation for the manufacturing of similar products sold directly by La Spirotechnique or produced under license all over the world.

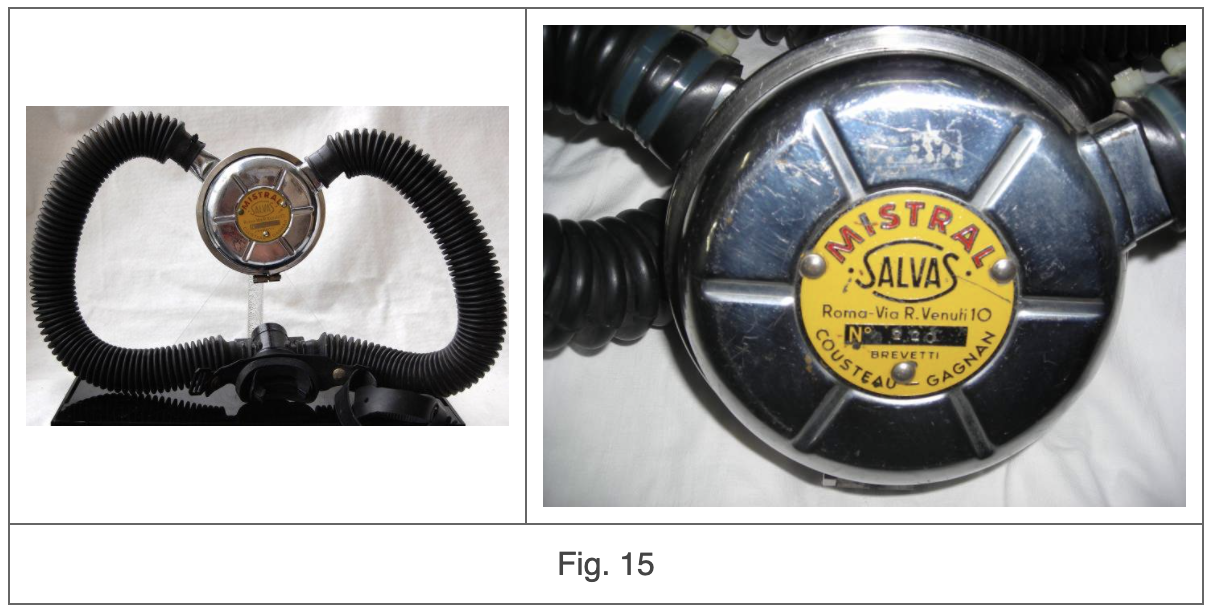

In Italy the Mistral officially landed through a license manufacturing agreement with the Salvas company of Rome, which likely manufactured and distributed it from 1956 to 1958 (Fig. 15) in few units and mainly for military and paramilitary organizations (i.e. Police Diving Unit). The Salvas company was already manufacturing, under the same license agreement, the Italian version of the CG-45 with the name “Acquasub”.

As you can see in the several versions manufactured and distributed in Europe starting from 1955 directly by La Spirotechnique, the Mistral would have been made with its front can provided with stiffening clews which were the same already used in the previous versions manufactured and sold by the Voit company in the USA.

In Italy again, before of the massive distribution of the Mistral directly with La Spirotechnique brand (through the Technisub company owned by Professor Luigi Ferraro and founded on 1962), this regulator was sold by the Spirosub company of Genova, starting from 1959 (Fig. 16) with some variants and options with respect to the French basic configuration (i. e. a different exhaust valve and mouthpiece provided with a surface-underwater selecting button).

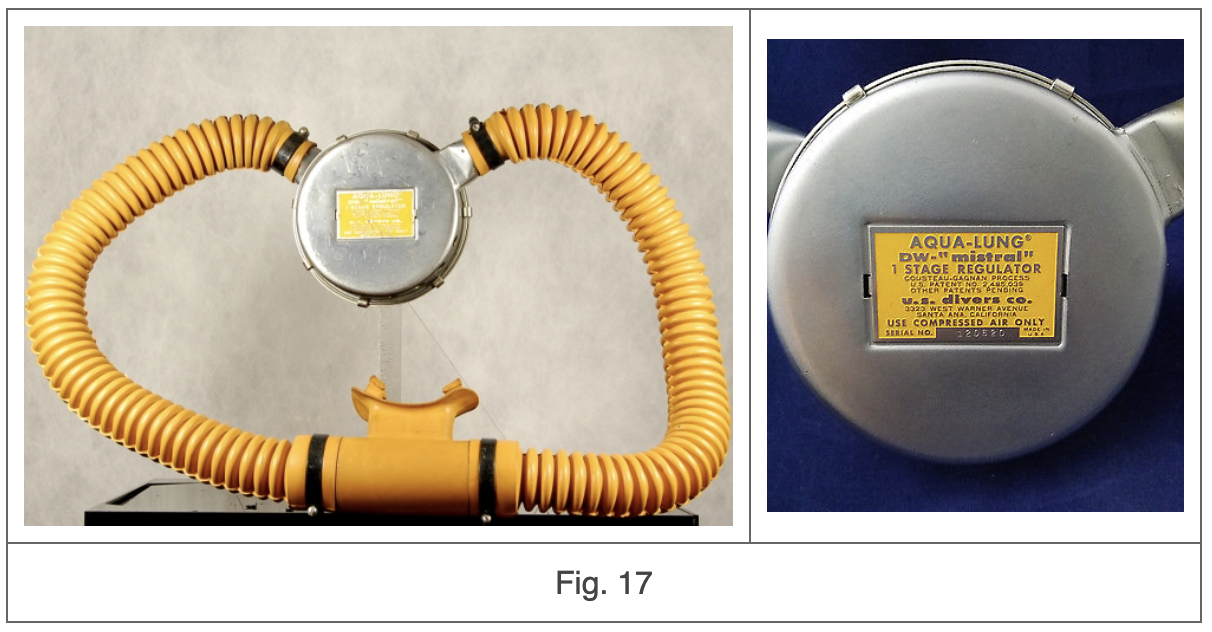

On the USA version manufactured by the U. S. Divers, the Mistral name would have definitively appeared in the official nameplate on 1959 with the “DW Mistral” model (Fig. 17).

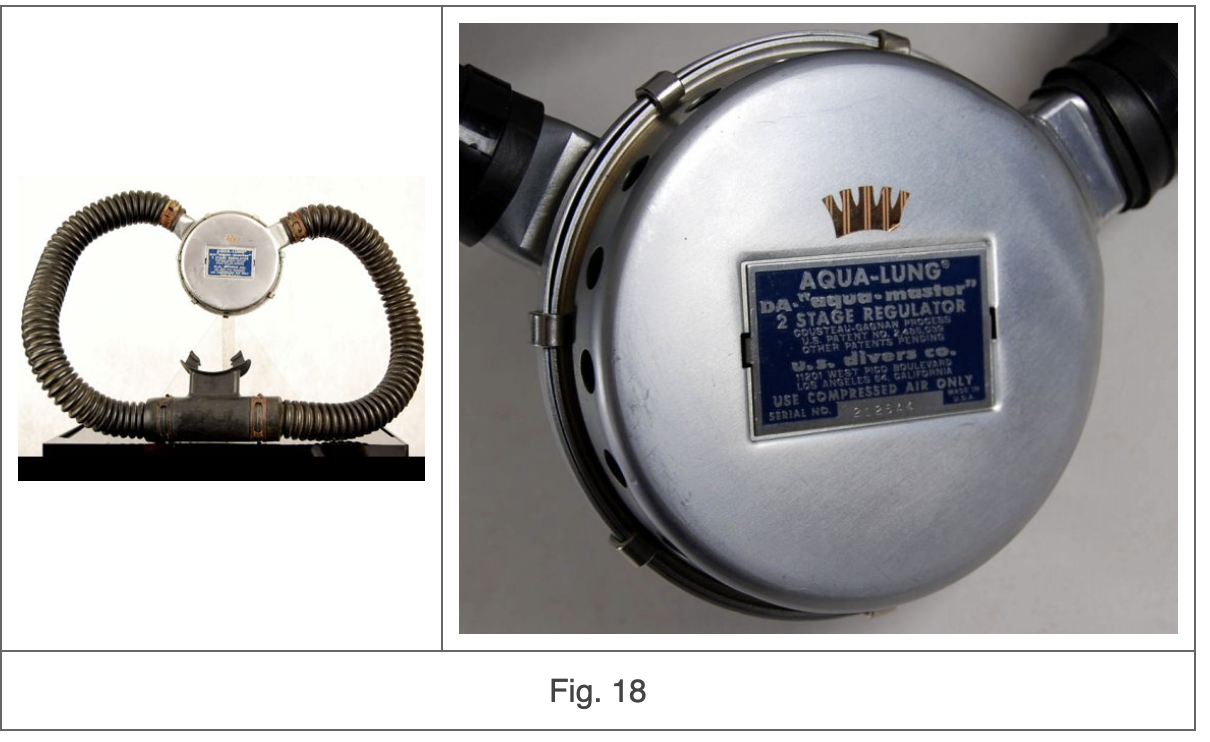

The “Venturi” effect invention was not limited to the single stage models only but extended by Gagnan to the following versions of the CG-45 as well. These versions have been sold for years on the North American market with the generic name of “Aqua Lung” and with several improvements (i.e. Navy Type DA, “DA Navy Appoved”) but without a final solution for the diver inhale effort issue. Therefore on 1958 the “DA Aqua Master” model (Fig. 18) which, thanks to the introduction of the Venturi effect, soon had an amazing market success in the USA with the manufacturing of hundreds thousands of units.

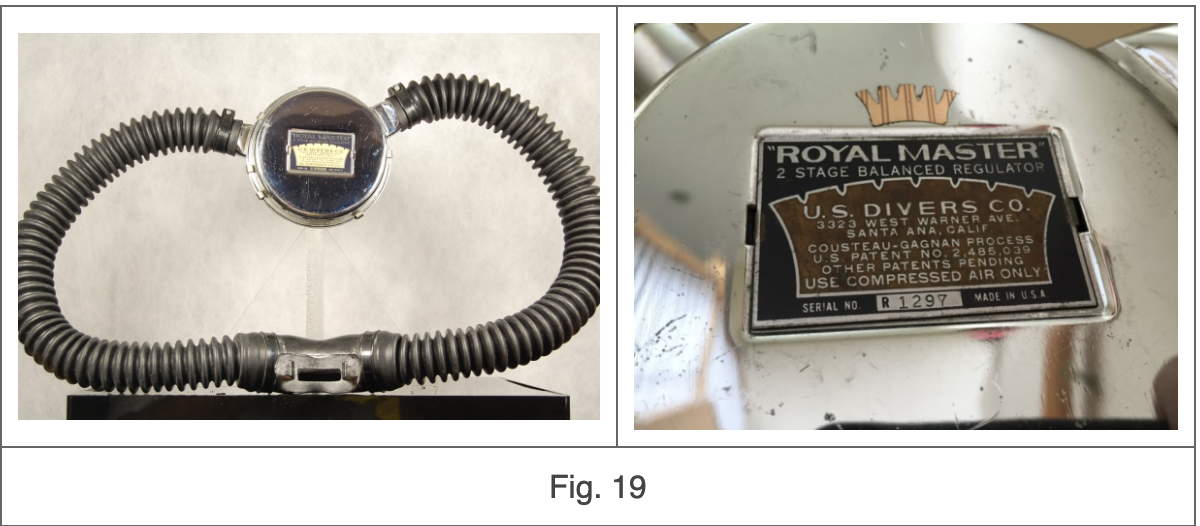

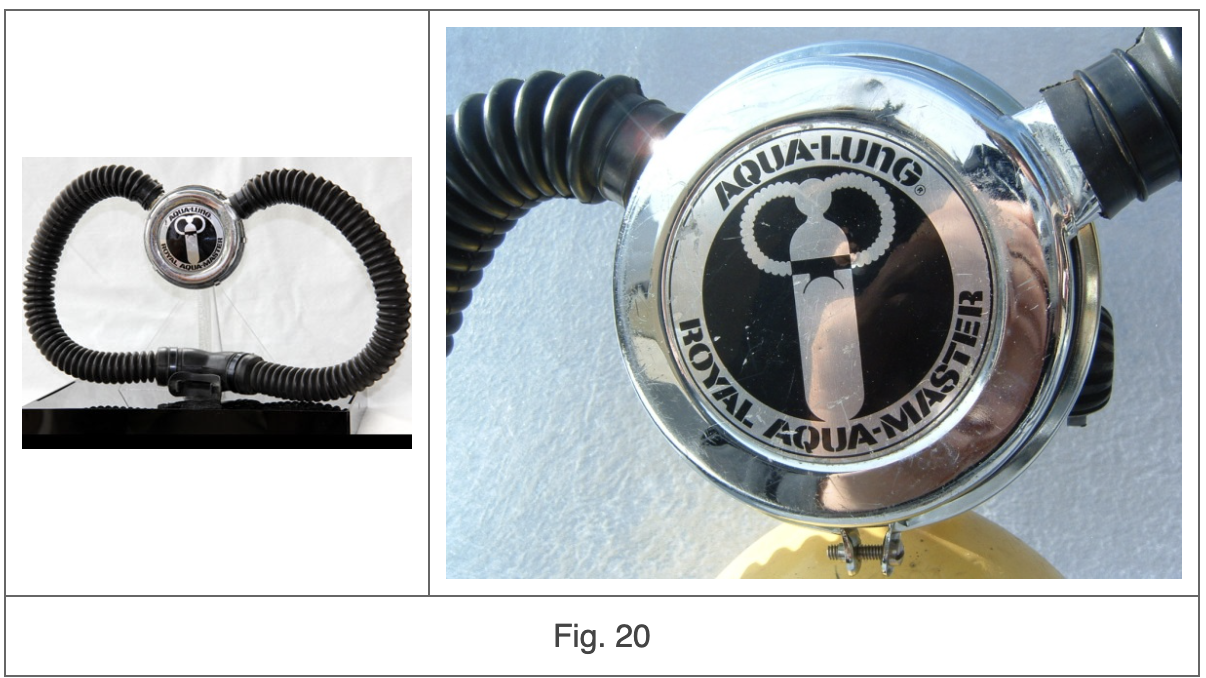

The refinement work carried out on the CG-45 would have concluded with the production of the definitive models provided with pressure balanced first stage, the DA Royal Master (Fig. 19) and the DA Royal Aqua Master (Fig. 20). These regulators remained in production in North America from 1965 to 1973.

The commercial success and fame the Mistral regular were quickly gaining all around the world did not prevent Gagnan in studying and proposing further improvements on this model. One of them was the same he has already introduced with success on the DA Royal Aqua Master two-stage version. This was the implementation of a pressure balanced first stage capable to maintain the regulator’s performances independent from the tank pressure value.

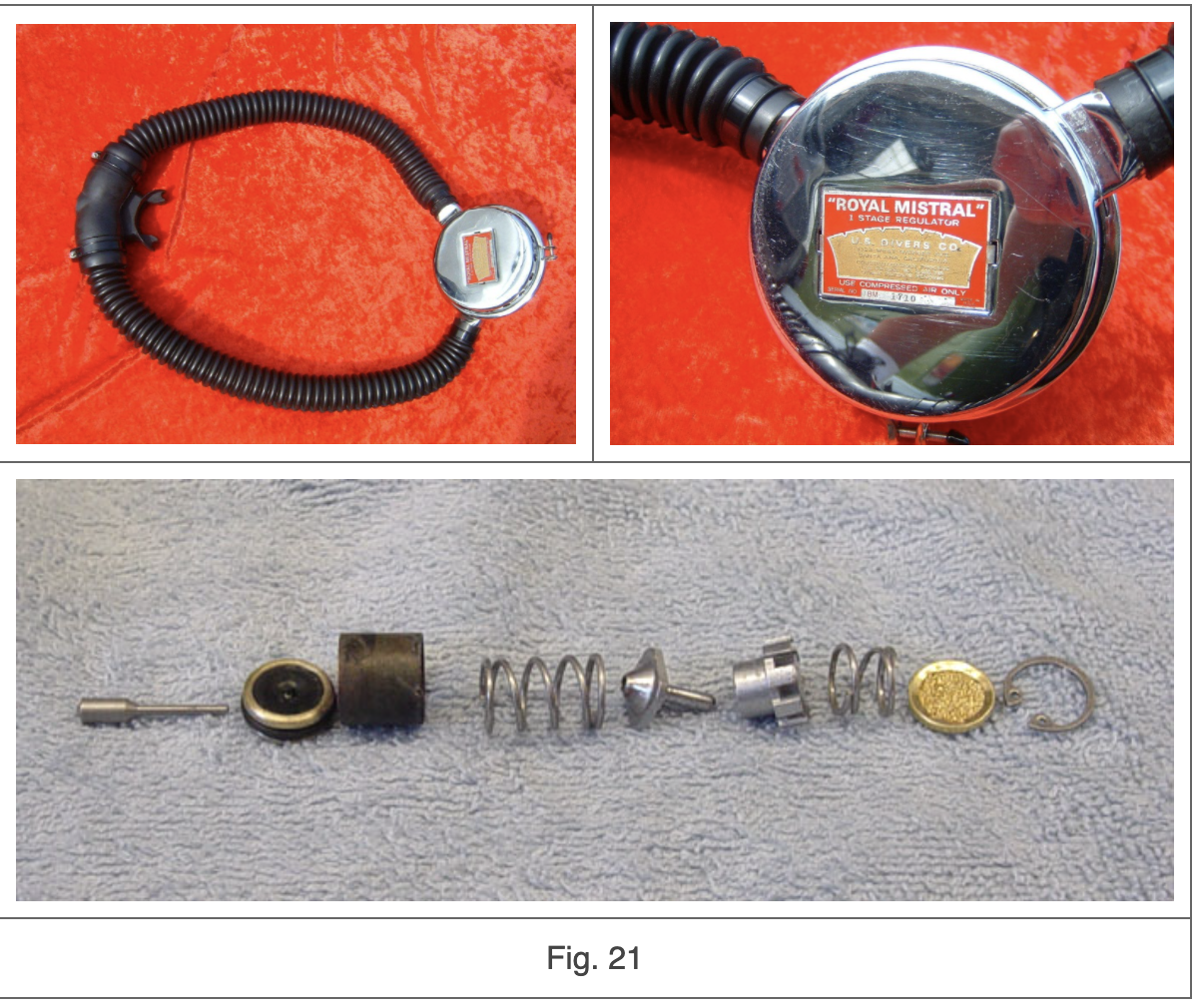

Gagnan then made the Mistral’s balanced version with the introduction of the “Royal Mistral” model on the North American market (1965-1967). However, the results were not satisfactorily due to a significant increase of its manufacturing complexity, which was not counterbalanced by adequate improvements in the regulator’s performances. And in fact this regulator remained in production only for few years (Fig. 21).

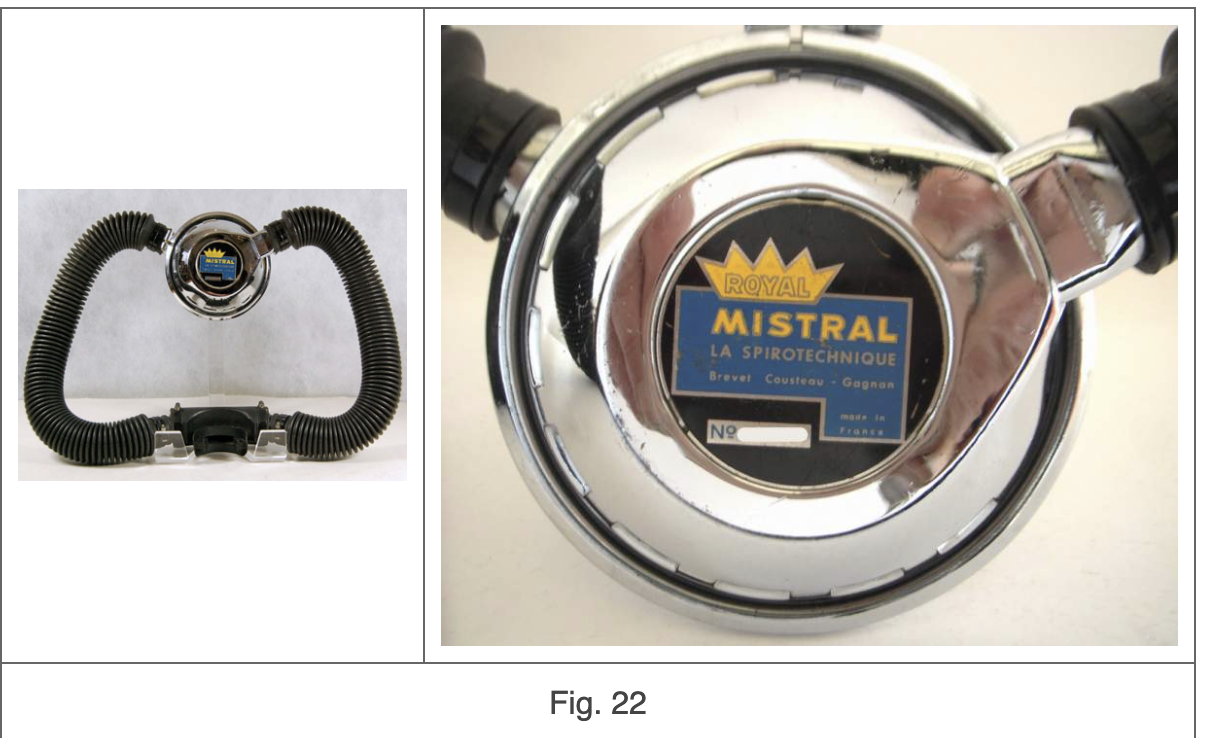

The U.S. Divers Royal Mistral should not be confused with the model directly manufactured by La Spirotechnique and introduced on the European market starting from 1963. This model was different from the previous Mistral in its top can, provided, instead of the circular openings of the Mistral, with square openings having bigger exhaust surfaces, in its hoses, having bigger sections and better stretching capability and for the use of a new mouthpiece equipped with “acquastop” valves (Fig. 22). These valves prevented the ingress of water inside the hoses when the diver lost the mouthpiece underwater.

In Italy, but also in most of the European country, La Spirotechnique for about two decades distributed the Mistral and Royal Mistral models only until this type of regulator was progressively replaced, on the middle of the ’70 years, by the two-stage single hose models. However many divers, having appreciated along many years of use, the Mistral’s and Royal Mistral’s reliability, robustness and simplicity, remained very tight to these regulators for a long time. Only in the years ’80 these divers, with disappointment, relegated them in the loft, replacing them with two-stages single hose regulators.

_______________________