After the rebuilt of the Nereide Pirelli First Series mask, a process described in one of my recent articles, chance meant that I came across a sample of another vintage Italian mask, the Medusa produced by Cressi of Genoa. This unit in particular seems to belong to the very first phase of production of this model, a phase that dates back to 1946, the year in which the industrial activities of the company founded by Egidio and Nanni Cressi began, even if we know that Egidio Cressi, employed in the Genoese branch of Banco di Roma have produced diving equipment (mainly masks and spearguns) on an artisanal level even before the start of the Second World War.

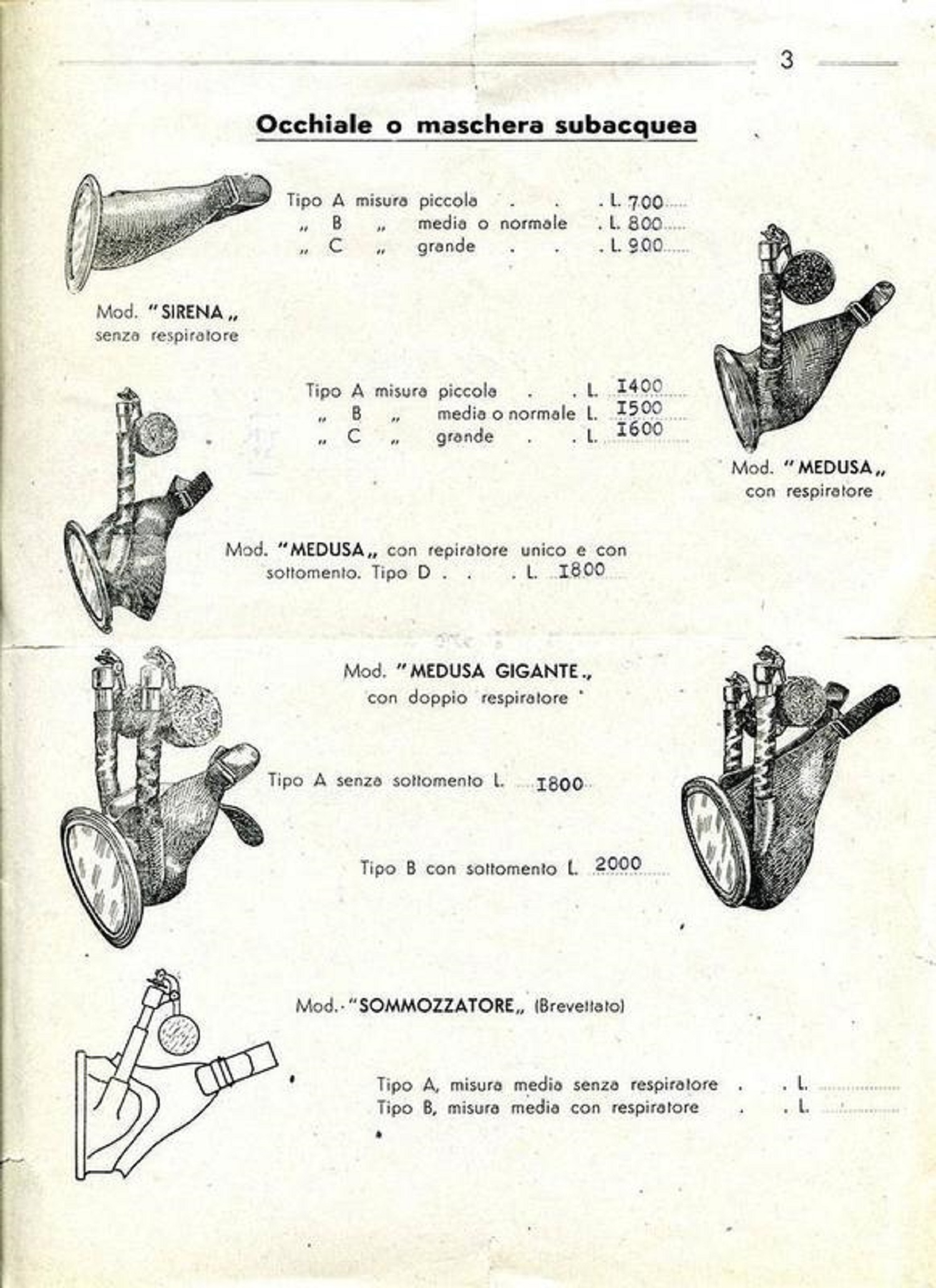

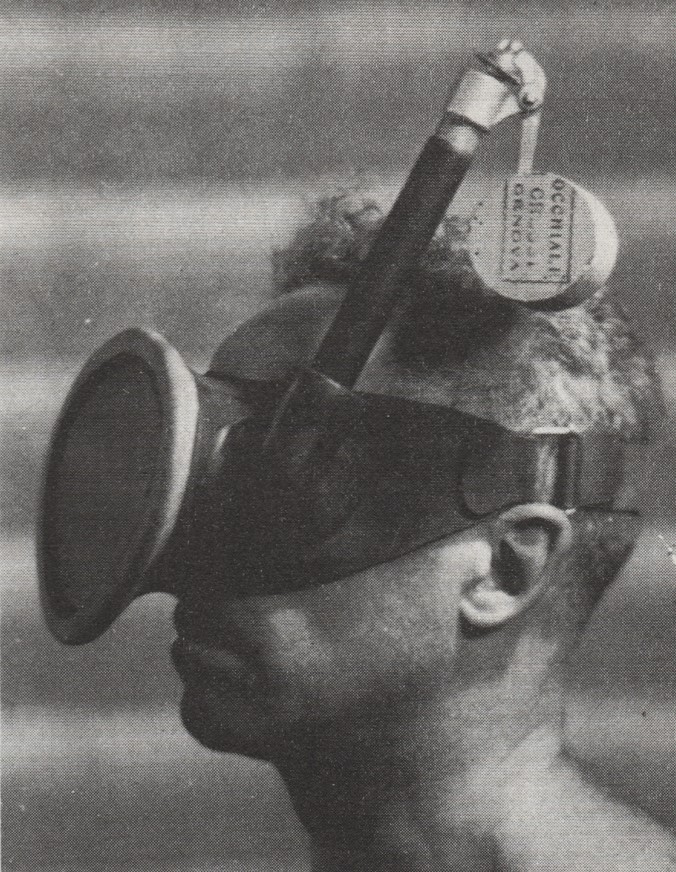

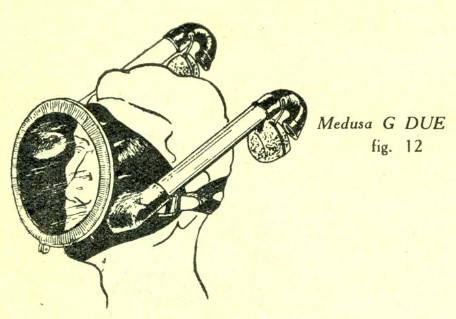

After long searches online and in several books and catalogs of the time, I was able to find only very few images and references of this model. The first official Cressi document showing this mask is the 1947 catalog (see Figure 1), a catalog which used, a common practice in those years, exclusively the drawings of the equipment rather than photos or virtual images, as would later happen in the following years. Looking at the photos of the several configurations of the Medusa (see Figure 2, Figure 3 and Figure 4), it would seem that Egidio himself and probably his daughter Didi acted as models in the creation of these images. This does not surprise me at all considering the financial and organizational challenges that the newborn Cressi almost certainly had to face in the very first years of its existence. Anything that could be done with internal resources and personnel was preferable to the alternative of requesting this type of performance from external companies, with all the expenses that would have resulted.

|

|

| Figure 1 | Figure 2 |

|

|

| Figure 3 | Figure 4 |

Comparing the photos with the catalog page in Figure 1, we can identify the model worn by Egidio in Figure 2 as " Medusa tipo B con singolo respiratore ", while the models worn by Didi Cressi are respectively the " Medusa tipo D con singolo respiratore e sottomento” (see Figure 3) and the “Medusa gigante tipo B con sottomento” (see Figure 4). The versions defined as " sottomento " were actually full-face masks that covered both the diver’s nose and mouth.

Beyond the typical application for freediving, this type of mask and some of its characteristic components (e.g. the front glass and the metal clamp tightening the body of the mask with the glass itself) were also used to produce the full-face mask integrated into the first model of oxygen diving rebreather (ARO in Italian), the AR47, put into production by the company starting in 1947 (see Figure 5 and Figure 6).

|

|

| Figure 5 | Figure 6 |

The unit from my collection is in excellent conservation conditions, as can be seen from the photos in Figure 7, Figure 8, Figure 9 and Figure 10. Unfortunately, both the snorkel and the automatic closing valve are missing.

| Figure 7 | Figure 8 |

| Figure 9 | Figure 10 |

Comparing that mask with the figures in the catalogue, this model is identical to the one shown in Figure 3 i.e. it is a “Medusa tipo D con singolo respiratore e sottomento”.

Looking at the mask in detail, it can be seen that this model used handcraft type and also rather complex and expensive solutions and processes. These solutions were in line with the knowledge and production methods available at the time but would not have been compatible with mass production and at reduced costs, a need that would have emerged in the years following the growth of both the number of units produced and the competition.

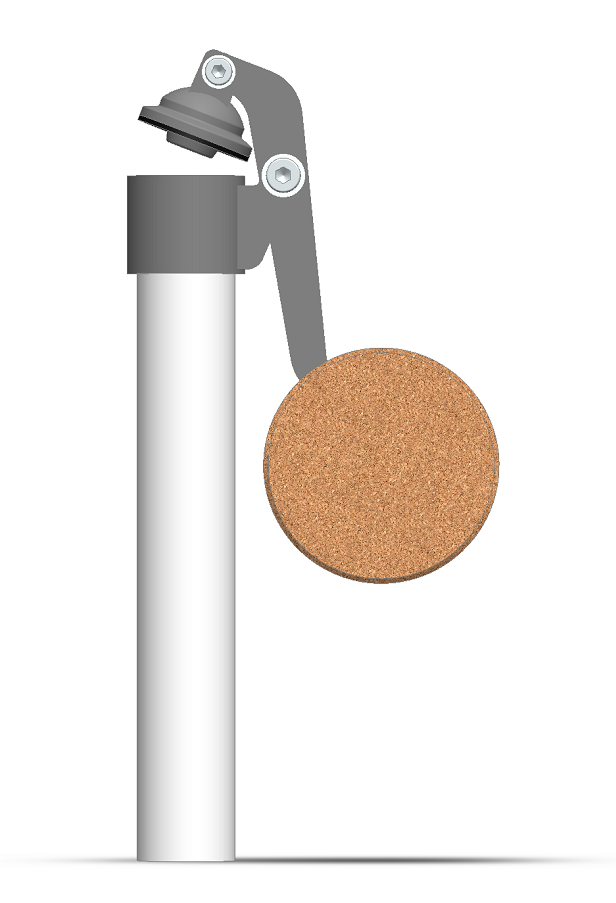

In particular, the automatic closing valve with cork floating device is an excellent example of a complicated and expensive solution and also not compatible with high production numbers. These production numbers and the associated cost reduction would have been achieved using injection molding technology for plastic and rubber materials, a technology that would become standard in the manufacturing of this type of equipment starting in the late 1950s. On the contrary, the valve of the first version of the Medusa was made with metal components, probably aluminum or brass, subjected to various mechanical processes and finally anodized or painted.

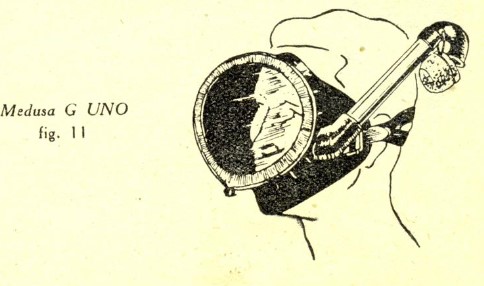

In addition, the cork floating device gave the idea of something made in the home garage rather than within an industrial organization. The customization of the various configurations was also achieved through handcraft processes. For example, the application of the shaped rubber connection where the snorkel tube was inserted was in line with this type of handcraft production methodology. In order to maintain the same mold for the rubber body of the mask, the solution consisted in gluing one (for the versions with a single snorkel) or two (for those with a double snorkel) rubber sleeves to the body of the mask, a body which had specific lateral connection areas, marked by the symbol of the head of Medusa, a well-known mythological character. The side where to apply the connection was previously pierced to allow the passage of air with the inside of the mask (see Figure 11 and Figure 12).

| Figure 11 | Figure 12 |

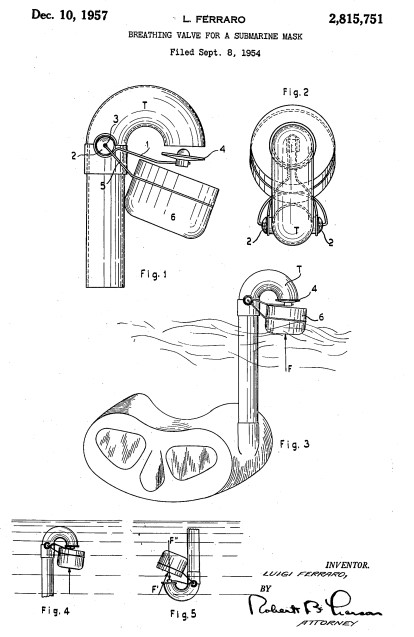

In the following years, the mask underwent various modifications and improvements starting with the automatic closing valve which Luigi Ferraro, a former Gamma frogman of the Italian Navy and a recipient of a Military Gold Medal for his famous exploits of Alessandretta and Mersina in Turkey during the Second World War, evidently set his sights on. Ferraro, working in those years for Cressi as Technical Director (see Figure 13), studied for a long time an improving solution for both valve performance and production simplification. Finally, he developed a valve project which was patented in the main reference markets (see Figure 14 which shows the first page of the patent filed in the USA).

|

|

| Figure 13 | Figure 14 |

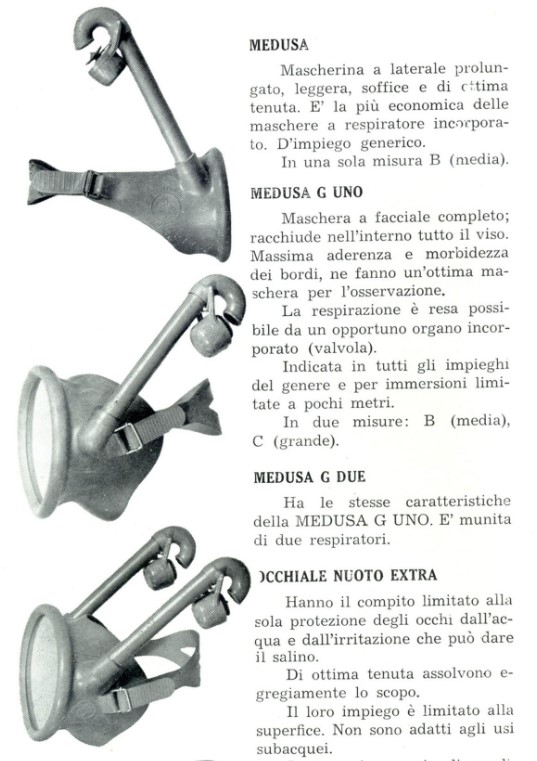

This new valve began to be installed on the Medusa masks probably starting from 1954, as shown in Figure 15 and Figure 16, taken from the 1954 Cressi catalogue.

|

|

| Figure 15 | Figure 16 |

As can be seen from the drawings taken from the catalogue, even if the valve is conceptually identical to the one illustrated in the patent, the float still appears to be made of cork while, starting from the following year (1955), all the components of the valve will be made in plastic materials (see Figure 17 and Figure 18).

|

|

| Figure 17 | Figure 18 |

In addition to the replacement of the closing valve, the other main changes that can be seen in the previous figures are the elimination of the metal clamp tightening the glass and the mask body, the integration of the rubber connections with the snorkel tube in the mask body (the connection is no longer glued but is now obtained directly during the molding process of the mask body), the modification of the head strap with the addition of a larger surface on its back part and, finally, the change of color from black to blue, a color that was receiving the greatest approval from the public in that period.

This mask model became very popular, although it did not have the same success as the other famous Cressi model, the "Pinocchio", also invented by Luigi Ferraro, a mask which has remained in production to this day. The Medusa, however, will remain in production for at least 20 years given that it was still included in the 1966 Cressi catalogue.

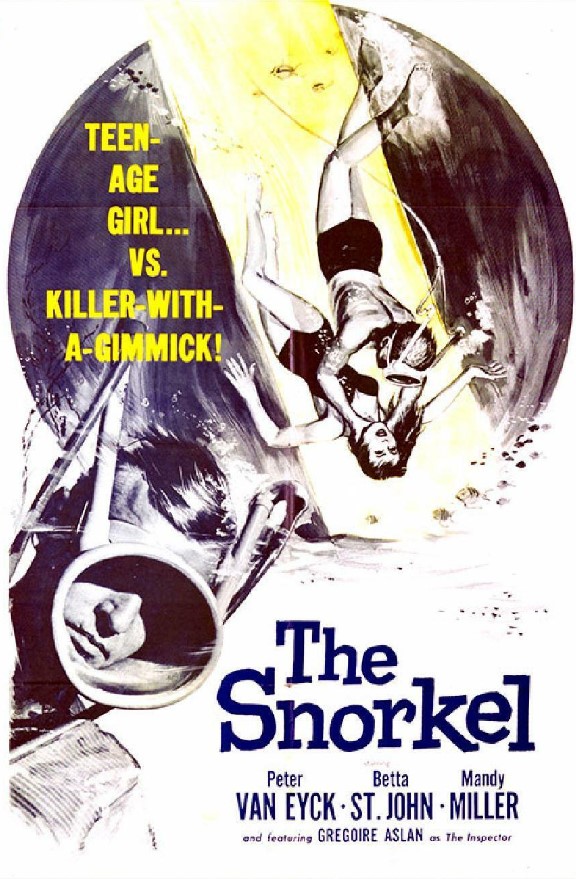

This mask was so popular in the 50s and 60s that it was even chosen to be the main element around which the entire plot of the English thriller "The Snorkel" is built, with the Italian title "Delitto in Tuta Nera" (see Figure 19 and Figure 20).

|

|

| Figure 19 | Figure 20 |

In this 1958 movie the protagonist, the writer Paul Decker, played by the actor Peter Van Eyck, kills his rich wife Madge, who was at her second marriage, by asphyxiating her with gas and avoids detection by hiding in a trap door under the floor and breathing air coming from the outside and channeled through rubber tubes connected to the Medusa G Due mask that Decker wears for as long as necessary (see Figure 21 and Figure 22). It will be the victim's young daughter Candy, had from Madge’s first marriage, inspired by a poster from Cousteau's famous movie "The Silent World" to understand the trick and finally unmask the killer.

|

|

| Figure 21 | Figure 22 |

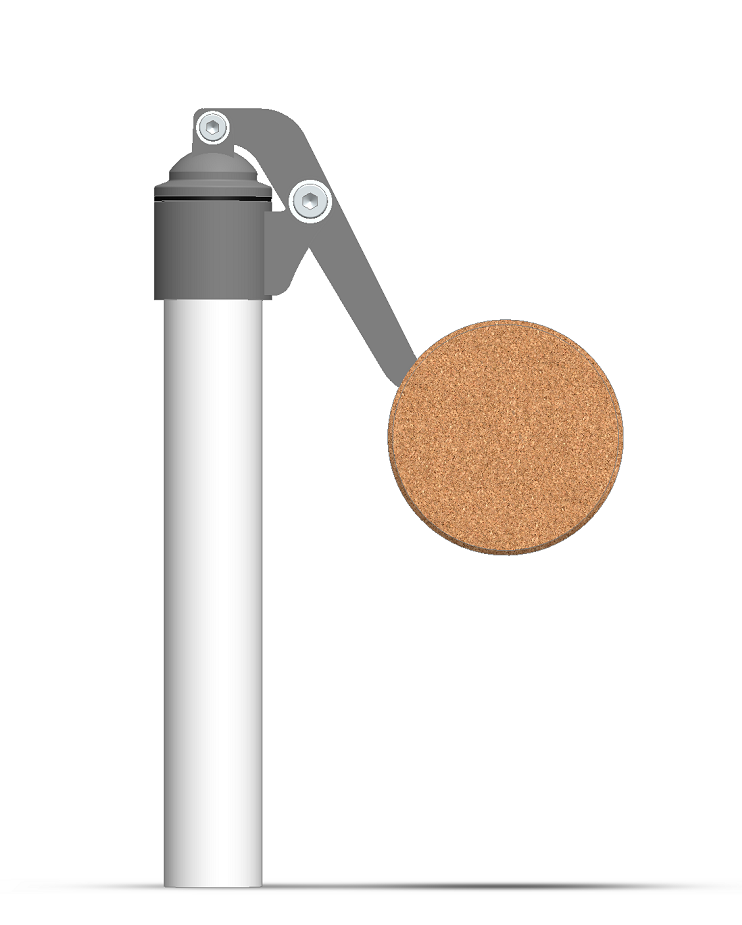

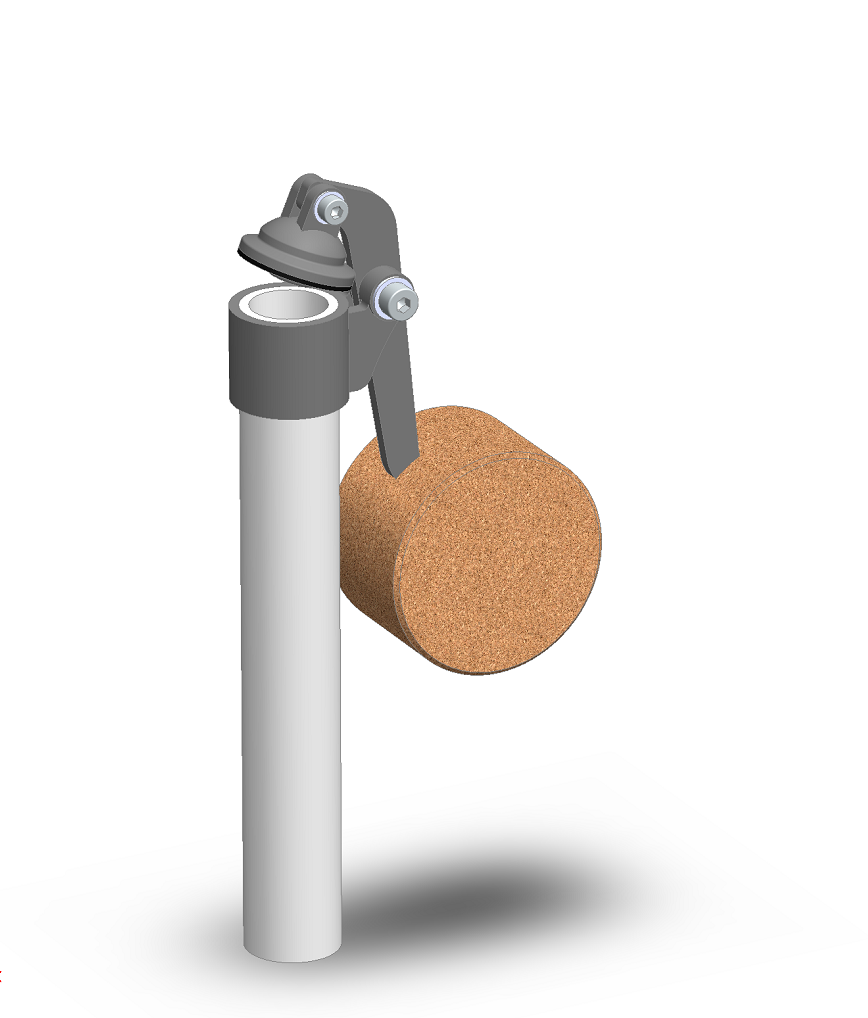

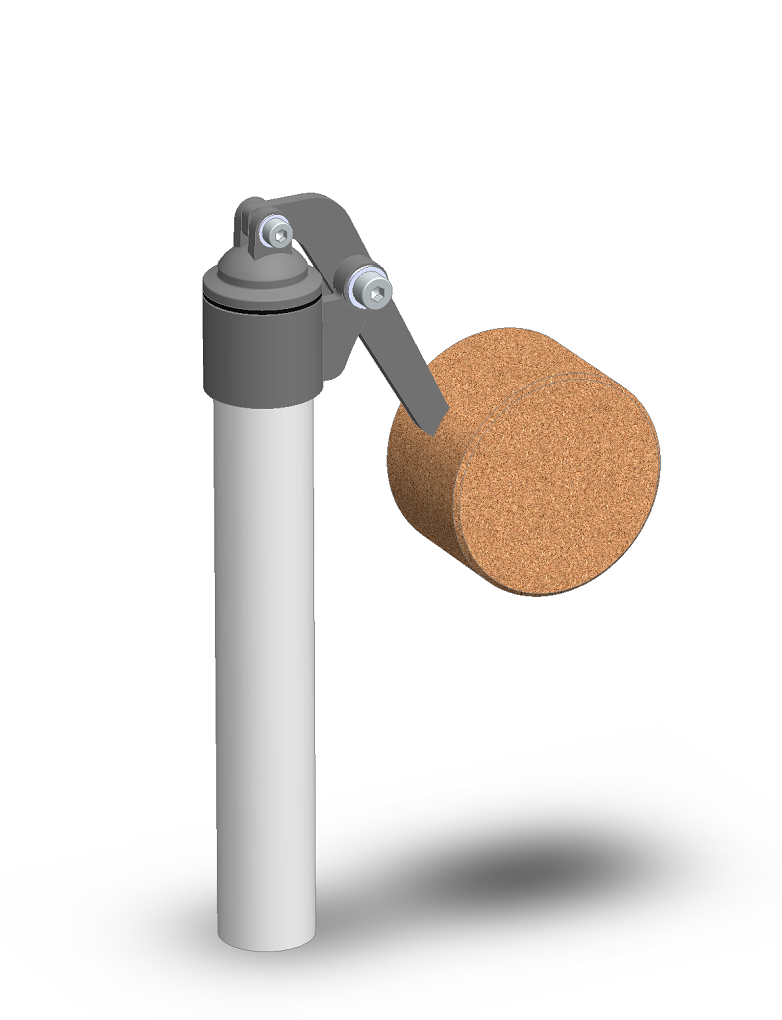

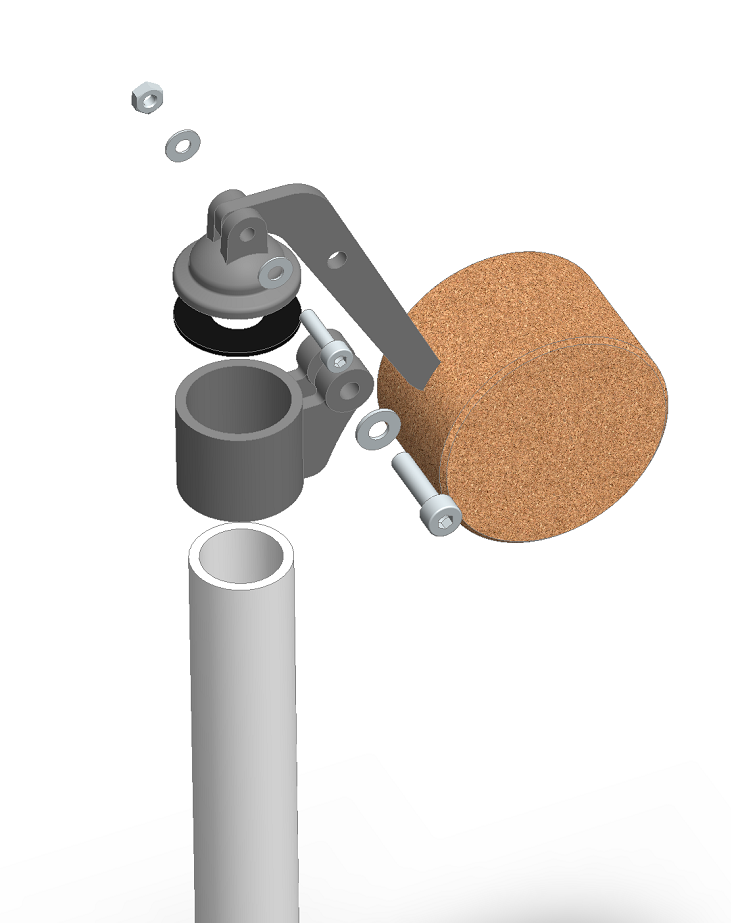

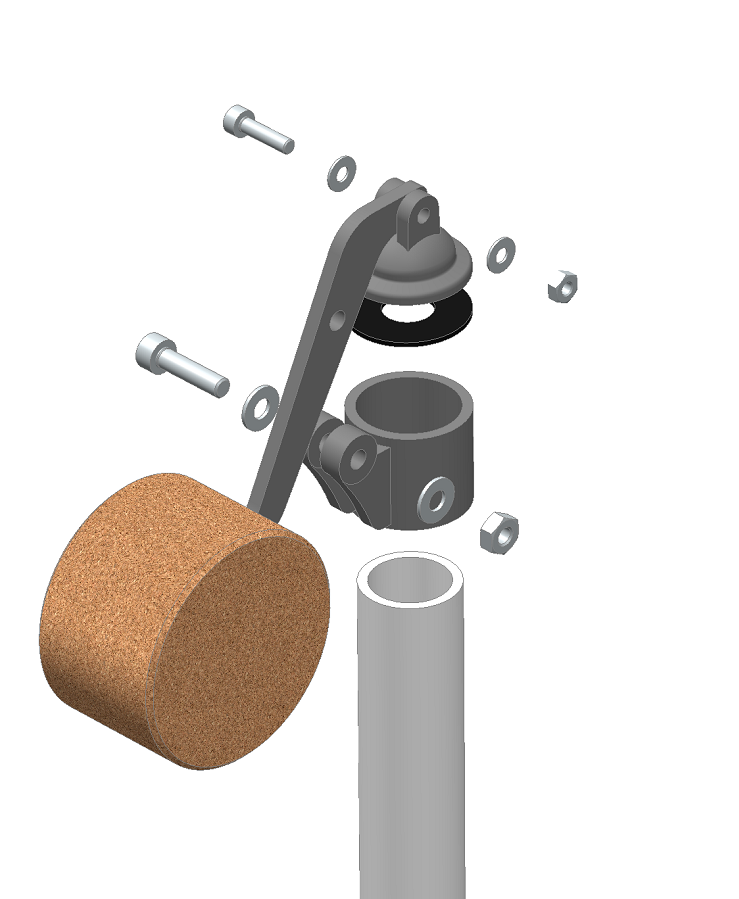

Unlike the previous rebuilt project of the Pirelli Nereide First Series mask, in this case I could not count on any samples from which to draw measurements and drawings. I was determined to rebuild the components of the original valve again using the 3D printing process but this time the 3D models of the missing pieces had to be obtained from dimensions estimated in some way from the very few photographs available, photographs shown in the first part of this article. Thus, after various attempts and adapting the 3D models "by sight" by comparing them with the similar details in the photos, the complete valve and all its components were rebuilt by CAD as shown in Figure 23, Figure 24, Figure 25, Figure 26, Figure 27 and Figure 28.

|

|

| Figure 23 | Figure 24 |

|

|

| Figure 25 | Figure 26 |

|

|

| Figure 27 | Figure 28 |

Even though the pieces of the original valve were most likely made of metal, I thought that, from an aesthetic and display point of view, making them in plastic material would have been absolutely in line with the purposes of this recovery project.

As already done in previous projects, I sent the models thus obtained to a 3D printing facility and thus obtained the missing pieces (see Figure 29, Figure 30, Figure 31 and Figure 32).

| Figure 29 | Figure 30 |

| Figure 31 | Figure 32 |

These pieces, after being sanded and calibrated for assembly, were painted with the usual chrome effect paint, an effect that was probably compatible with the surface treatment of the original metal pieces.

For the cork float, as done in the previous project to recover the Nereide mask already mentioned, I turned to a carpenter equipped with a wood lathe who, starting from the usual wine barrel cork plug, developed the final part ( see Figure 33 and Figure 34).

| Figure 33 | Figure 34 |

Finally, to give a touch of greater realism to this project, I had the special rubber stamp made (see Figure 35) which was used to mark the cork floating device used in the manufacturing of the very first units of the Medusa mask, as can be seen by observing the Figure 2. Using this stamp, the cork floating device made by the wood lathe could also be marked as the original pieces (see Figure 36).

| Figure 35 | Figure 36 |

For the snorkel tube, white in color as shown in the photos in Figure 3 and Figure 4, I had no problems finding a piece 1 meter length of PVC with an external diameter of 20 mm on eBay. This piece was cut to the right length, based on the measurements obtained from the available photos.

At this point the mask could be assembled and completed and the final result can be observed in Figure 37, Figure 38, Figure 39, Figure 40, Figure 41 and Figure 42.

| Figure 37 | Figure 38 |

| Figure 39 | Figure 40 |

| Figure 41 | Figure 42 |

For the connection between the valve body, the lever and the cap I used M3 and M4 stainless steel bolts and self-locking nuts. The sealing surface between the cap and the top of the snorkel tube was provided by inserting a self-adhesive rubber disk.

Finally, I close this article by reporting a statement found on the Cressi website, a statement that I found while navigating the net in finding information on the Medusa mask. With reference to one of its latest models of full-face mask for snorkeling (see Figure 43 and Figure 44), masks which in recent years have become very popular and widespread among those who approach this activity for the first time, the Genoese company declared: “This model is the evolution of the first full face mask ever produced, called Medusa, created in 1946”.

|

|

| Figure 43 | Figure 44 |

This statement off course, which initially left me a little confused, could only apply to this type of mask, excluding those which were part of the Italian Navy frogmen oxygen rebreathers devices used during the war. However, this sentence made me think but, in the end, I had to conclude that this statement was essentially correct. In fact, all the main elements of this latest model are also found in the original Medusa mask, and in particular:

• it covers both nose and mouth

• It has an integrated breathing tube equipped with an automatic closing valve with integrated floating device

• It does not allow ear compensation (unless you use the classic nose clip which was quite popular in those years)

• It has a ventilation system that reduces the possibility of the glass fogging up (very primitive on the Medusa, consisting only of a rubber septum glued to the inside of the mask which forced the air to follow a circular trajectory before being inhaled)

Beyond the enormous differences between these two models from the point of view of materials, production processes and aesthetic and ergonomic solutions, obvious differences if we think of the almost eighty years that separate the production periods of these masks, the main variant from an operational point of view is that the Medusa does not have a dedicated water drain valve.

And therefore, this rebuilt project, in the end and as often happens in similar cases, also allowed me to dig deeper into the history and the main phases of life of one of the most iconic and representative mask models of the entire evolution of diving equipment developed during one of the most fascinating and fruitful periods in the history of this sport.

_____________