Everything began in 1890 in Holland, more precisely in Amsterdam where the young entrepreneur Goossen Leendert Loos establishes the Loos & Co. At that time, Loos main activity was trading the well-known Victoria mineral water; however, considered business expansion, he begins importing and distributing anhydride to gas mineral water.

LOOS & CO HEADQUARTER

In 1910, Loos continues to expand his enterprise including, among his products, the trading of oxygen which he will begin to produce later on to supply the Dutch market. Years pass by, and he begins to import torch for metal welding and valve reducers from Germany.

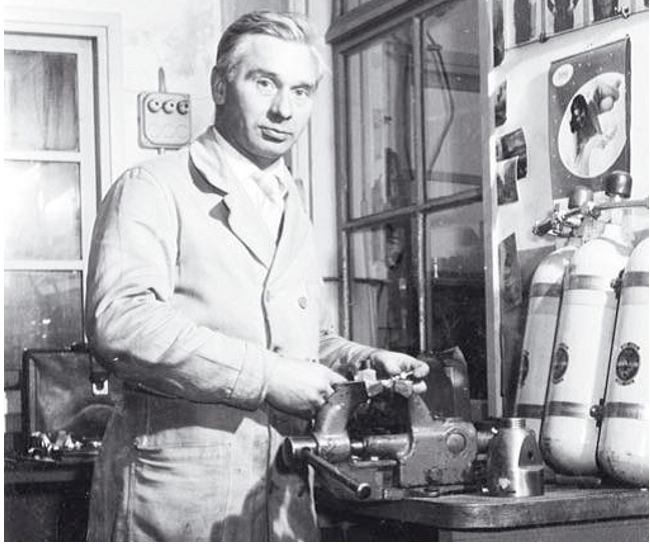

In 1928, at the age of 15, Jan Van Buuren entered the service of Loos & Co. showing to be a talented youngster from the beginning. Soon he learned from his master, the German Gilrath the job of assembler so that, at the age of 18 he becomes welding instructor; in 1930, he proposes to design a regulator not affected by upstream pressure, which could have solved several problems, with a “lifetime” duration. Since the 30s, the company began the distribution of medical appliances; subsequently, Van Buuren specialized in the repair and resolution of problems of so called “traction engines” used for anesthesia, so that his hobby became to experiment and improve the American equipment imported. Years go by; reached a certain dimension in 1938, the company changed name in G.L. Fabrieken N.V. of Loos & Co. It is in this occasion that, as factory brand, for the first time, Loosco nickname is used.

Let’s do a time jump to the end of the second world where everybody’s priority was to rebuild. As in other companies, also at Loos & Co. was clear that there was a lot to do to clean and repair the several ports in the North Sea, under and below water; so, they should have been ready for this challenge. Said and done. At the beginning of the 50s, a request comes from the Civil Defense of Belgium for the supply of fire-fighting breathing apparatus able to be used also underwater. Knowing that he did not have nothing to offer of this kind, Van Buuren begins immediately his experiments putting together an air compressed bottle and Scott appliances of American origin used for anesthesia, that Loos & Co. was selling in his product range. He begins to dive regularly in a swimming pool to try all modifications he was making to the gear; results quickly arrived and soon they brought to the development of his first experimental diving regulator. Path was set; with Van Buuren knowledge and ability, this step was short.

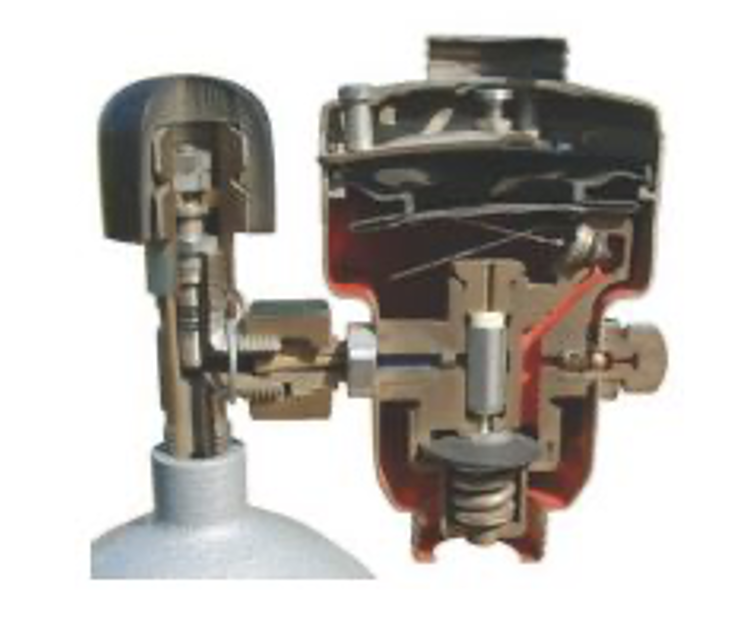

After having created in 1955/"56 the innovative compensated regulator valve (although the compensated valve was invented by Georges Commeinhes in 1944, patent number fr989.153° but, probably, Van Buuren did not know) which will be the base of all "Dive Safe Diver Equipment" of Loos & Co., Van Buuren builds the first single-block double stage regulator with two hoses with compensated regulator valve.

One day, talking about it he said "I made thousands of drawings before finally developing the right one; I knew exactly how it should not be, but I did not have any idea about how it should have been". The first "EGG Loosco" regulators were put on sales in August of 1957, nicknamed in this way because of their unusual design which recalls the egg’s shape.

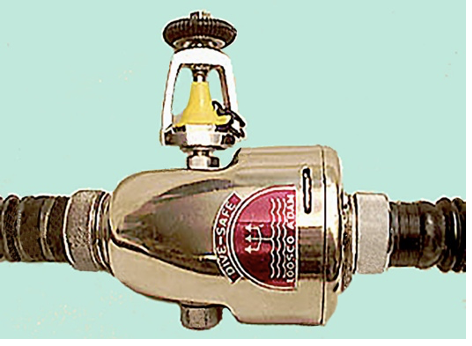

Loosco Dive Safe "Egg"

Immediately after that, on request of the French Navy, Loosco and Jan Van Buuren tested one of their regulators previously sealed, since they were afraid of a conspiracy between the French Navy and Cousteau who, probably, was improving his regulators. Tests were done in Marsiglia from vessel lieutenant J.P.H. Huijskens, author of the "Safe Diving" pamphlet of Loos & Co.; these tests were made up to a depth of 150 meters, surprising everyone in an extremely positive way with specific reference to its innovative valve, reporting that "the valve without pressure" functioned "in an excellent way". In fact, while regulators built at that time still did not have any way to compensate the high pressure drop from the tanks, the EGG regulator called off the problem thanks to its innovative valve with balance high pressure.

J.V. Buuren

Unfortunately, as often happens, ambitions last little and, in 1961, Loosco begins to lose his international competition with Spirotechnique, his main competitor which, in 1963, presenting in the market its double-stage Aquilon regulator with single hose, in few years proclaimed the death of all double-hose systems. It is in this occasion that Loosco, changing Van Buuren with other two engineers, will definitely end this project which probably was too ambitious. Although the EGG regulator incurred in many difficulties which revealed its premature end, its heart made by the compensated regulator valve of Jan Van Buuren never died; this valve is still used today in the medical industry for its reliability and almost no maintenance. The company continued to produce diving gear as part of its large range of breathing devices also after its merge with Hoek in 1972.

Its functioning

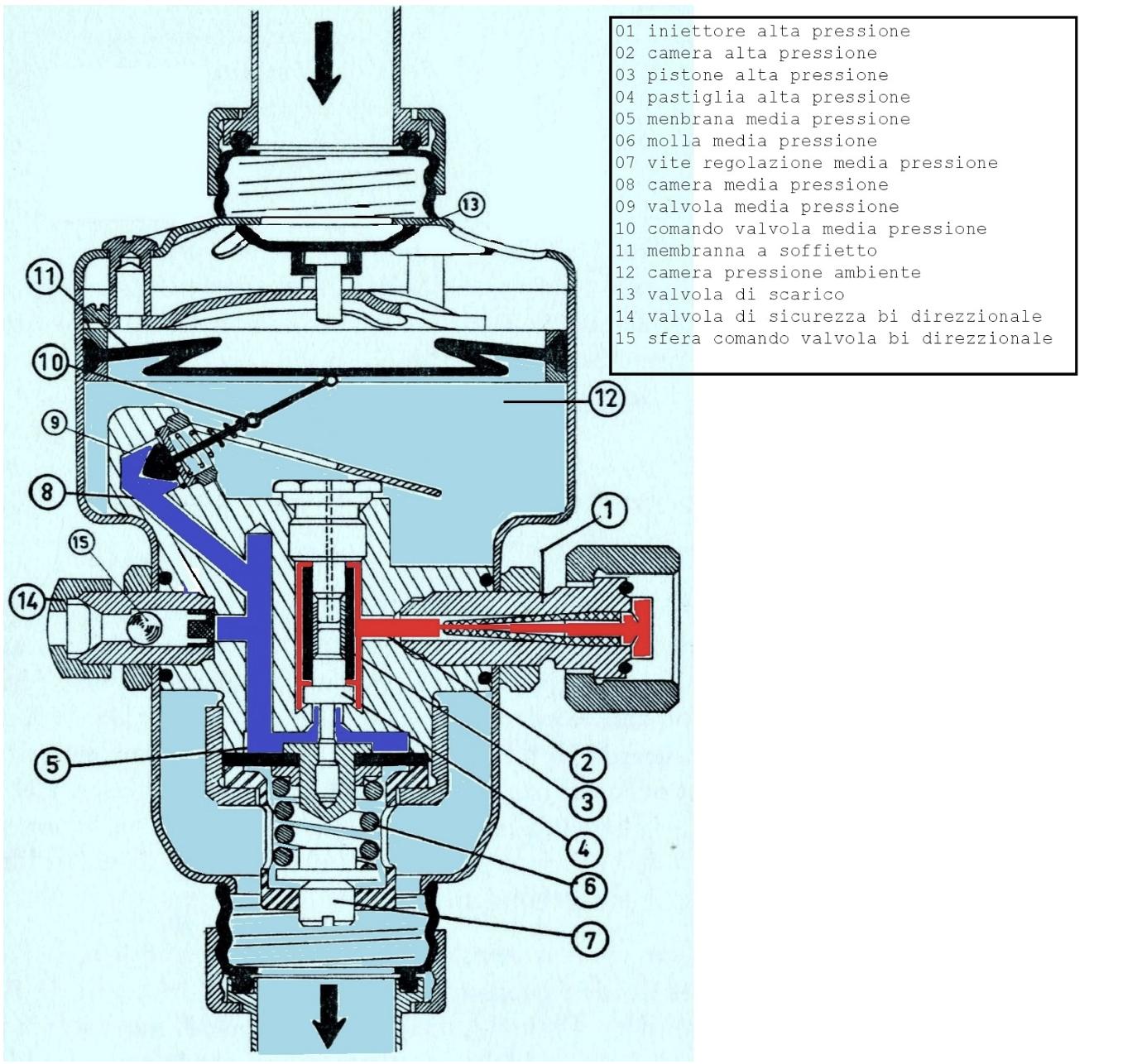

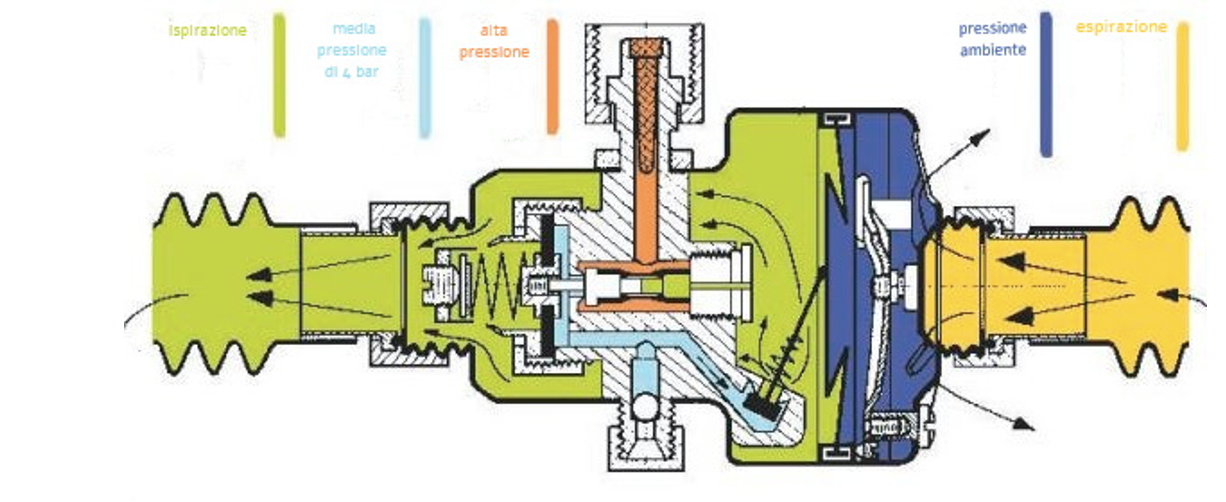

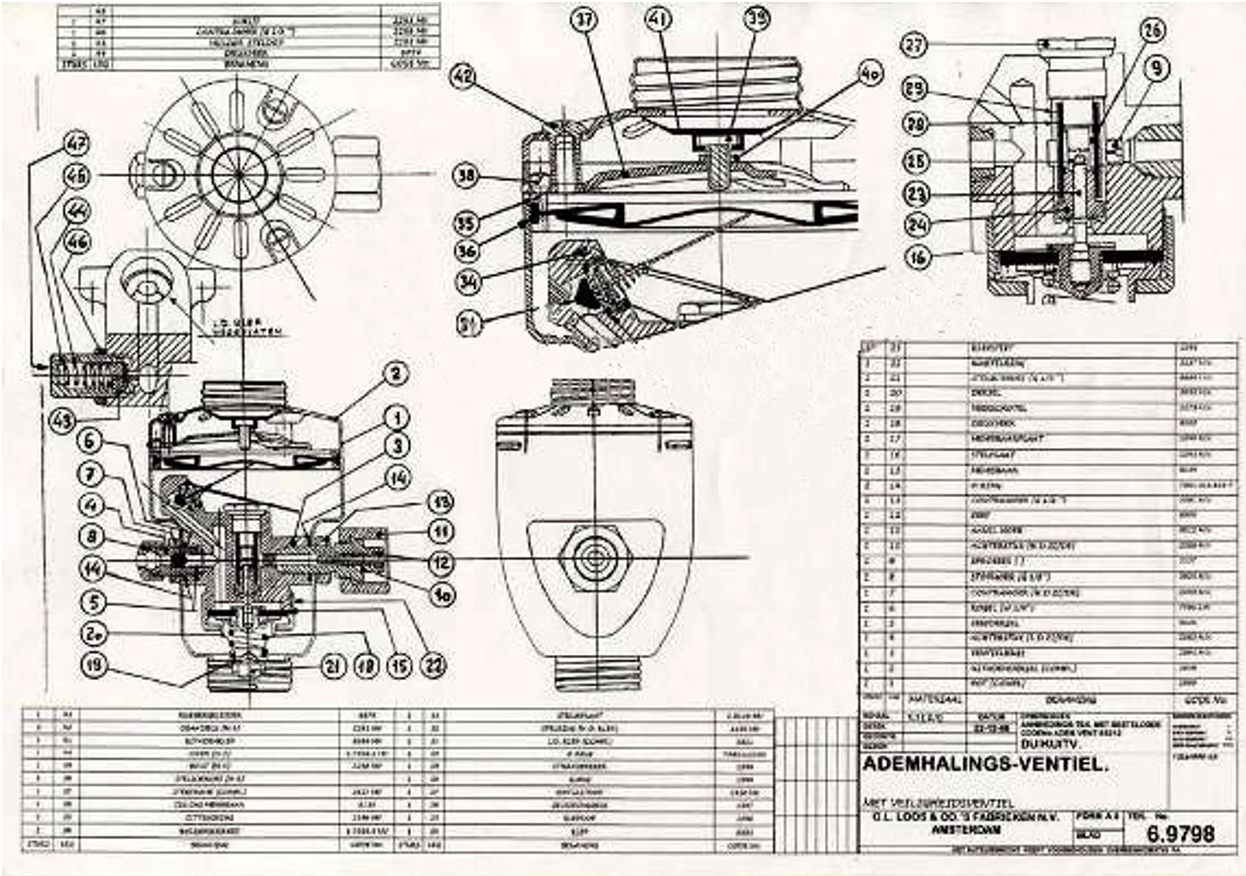

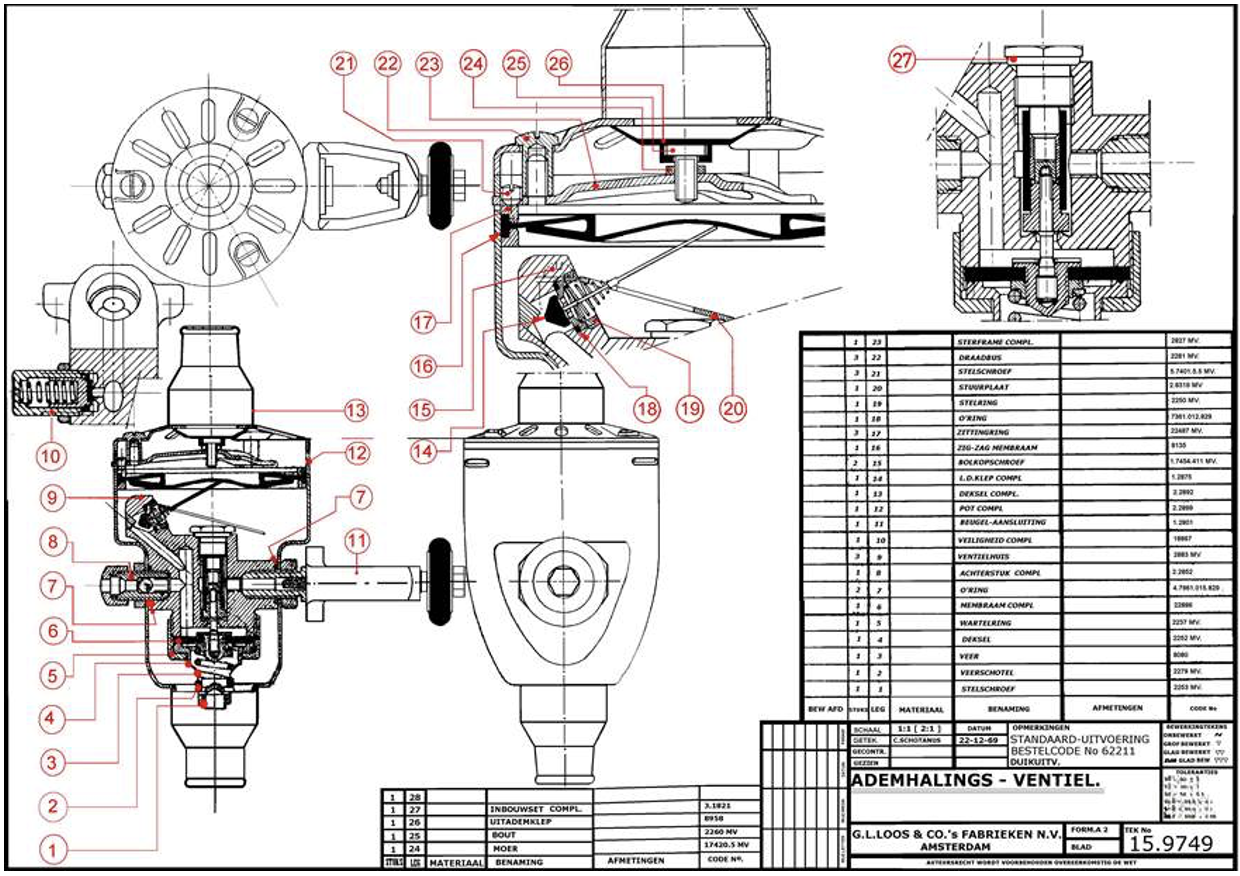

One consideration to make it that the EGG regulator is based on a series of innovative ideas not present even in today’s most modern compensated regulators with single hose. In fact, by checking its scheme, the first thing that can be noticed immediately is that in the high-pressure piston (3) there is no influence of the high pressure coming from the tanks, as it happens in the other Spirotechnique regulators.

Another characteristic of the Loosco regulator, which still today remains unique, is that intermediate pressure inside the membrane chamber depends on the spring pressure plus the ambient one; however, considered that the water pressure on the diaphragm which divides the ambient pressure chamber acts only indirectly on the main membrane, the two whole control stages remain totally insulated from water and, consequently, dry. This is of vital importance for safety if we consider the possibility of a mechanical block for a possible ice formation. The EGG regulator was produced from 1957 to 1975; it was used until 1980 by a relatively large number of professional and recreational divers mainly Dutch; its manufacturing numbers are not known.

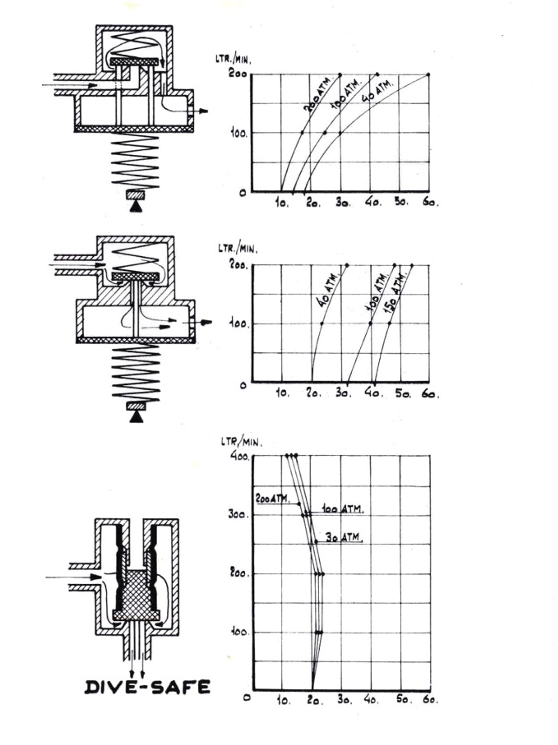

Jan Van Buuren target to build his regulator was to maintain constant the intermediate pressure supplied to the second stage, so that the regulator valve could be calibrated with a minimum resistance without sustaining interferences in pressure drop inside the tanks. In reality, what was obtained with the EGG regulator is incredible for a 1957 regulator, and it is even more compared to the competitors’ regulators of that age: what was achieved is that the intermediate pressure remains constant at 4 bars with a tank pressure between 30 and 200 bar, while the breathing effort remains between 18-20 mm of water column with a maximum air output of 400 liter/minute.

OUTPUT DIFFERENCES IN REGULATORS’ VALVES

PARTICULAR OF EGG REGULATOR VALVE

Model

Three different models of Loosco EGG regulators appear in the market with differences only in the regulator body, while in all of them the “heart” and tank connection, a ¼ gas threated female nut were the same. The first version that we call V1 is the original shape, designed for professional diving: it presents some threated connections for the hose outlets. The second V2 version was identical to the first one, except for the presence of two rings in its body, used for the direct attachment to the diver by means of belts included with the regulator; air was supplied not from the tanks but from the surface by hose. In the last V3 version, recommended above all for recreational divers, the thread for the screw connection of the hoses was replaced to receive the corrugated hose such as Spirotechnique to be fixed by fasteners.

DIFFERENCES AMONG THE 3 EGG FIRST STAGES

There is also a smaller EGG version, to be adapted to a full-face mask, to use in depths up to 5 meters or in dry places where the atmosphere was unbreathable. The system was supplied with a pressure of around 4,5 bar from the surface; it was equipped with belts to fix it to the diver, and with one high pressure hose some meters long. Unlike his older brother, this regulator was a cheap product that often, was thrown away: for this reason, today is not easy to find one in good condition.

SMALLER EGG VERSION

La versione V1 dell'Egg

La versione V3 dell'Egg

Sezione trasversale dell'Egg

Il catalogo del Loosco Dive Safe "Egg"

___________________